-

Assessing the physiological properties of the human body in real time using a contact measurement device is a key asset in modern healthcare1. Through the skin, we can assess a plurality of thermal, cardiovascular, and metabolic properties of the body using arrays of miniaturized sensors that are arranged in smart textiles and wearable devices2,3.

Optical fibres provide an alternative approach to electric sensors4. Several optical-fibre sensors, such as fibre Bragg gratings, enable the multiplexing of multiple sensing locations along a single optical fibre and localised detection5. The design of the fibre also plays a crucial role in these devices: while single-mode fibres have a miniaturised design that allows integration with fabric6, multi-mode fibres with larger cores facilitate light coupling, and therefore, can operate with small and low-cost hardware, such as smartphones7,8.

From a systems standpoint, several studies have been conducted for the realisation of physiological and biological contact measurements of body properties. Smart textiles integrate optical-fibre sensors into clothes, garments, or accessories using flexible optical fibres. Examples of these structures have been proposed using optical fibres that are sewn into everyday and sports clothes9,10, integrated into garments11, or embedded into shoes12. Another approach relies on the fabrication of wearable elastic bands with integrated sensors, which are used in thoracic devices5 or wristbands13.

In terms of application, three major domains can be identified. The most common use of fibre-optic sensors in wearable devices exploits the sensitivity to strain, using either wavelength-shifting sensors (such as Bragg gratings)14 or intensity sensors that detect fibre stretching15. The first approach has been proposed for real-time breathing analysis, relying on multi-point sensing by leveraging the high accuracy and large multiplexing capability. The second approach offers several low-cost opportunities, as it can rely on battery-powered hardware or smartphones in either single-point or multiplexed networks16. Strain sensing has been employed mainly in heartbeat rate and respiratory detection, as proposed by Leal-Junior et al. for digital discrimination in the frequency domain17, and in rehabilitation, as proposed by Li et al. using surface-treated plastic fibres18. A second application measures the body temperature, usually through Bragg gratings that inherently have thermal sensitivity; this is usually achieved by embodying the sensors into an elastic band or fabric that enables full contact with the skin in the sensing zones6. Other studies have relied on the online measurement of blood pressure using wearable fibre-optic devices13.

The most significant emerging trend is the use of optical-fibre sensors to exploit the biological properties of the skin through sweat sensing19. Sweat is rich in biomarkers that can be assessed on the surface of the skin, during both sporting activities and daily routines2,20. In sweat, we can assess glucose levels that can be associated with diabetic diseases, though still with limited specificity21, while high levels of metabolites such as azelaic acid and suberic acid in sweat can be associated with cancer cell proliferation22. Very few works have addressed wearable fibre-optic devices for sweat sensing: the most recent work was reported by Zhang et al.23 using a fingertip mount for a fibre-optic sensor that is capable of detecting motion and sweat pH.

The future of the field will largely revolve around the properties of optical fibres used in wearable and contact sensors. If engineering works have substantially addressed the size, function, and operation of wearable devices, as well as their hardware (compactness, power consumption, and connectivity), there is much room for optimising the fibre itself, tailoring it to specific sensing and transmission properties. Polymer fibres and coatings have represented the current direction to date. Li et al.6 presented a polymer-coated glass fibre with a thermal sensitivity that was 15 times higher (150 pm/K). Notably, Leal-Junior et al.7 introduced a light polymerisation spinning process that is capable of extending the stretchability of fibres by up to 17%, which is an excellent property for sensors that are embedded in clothing.

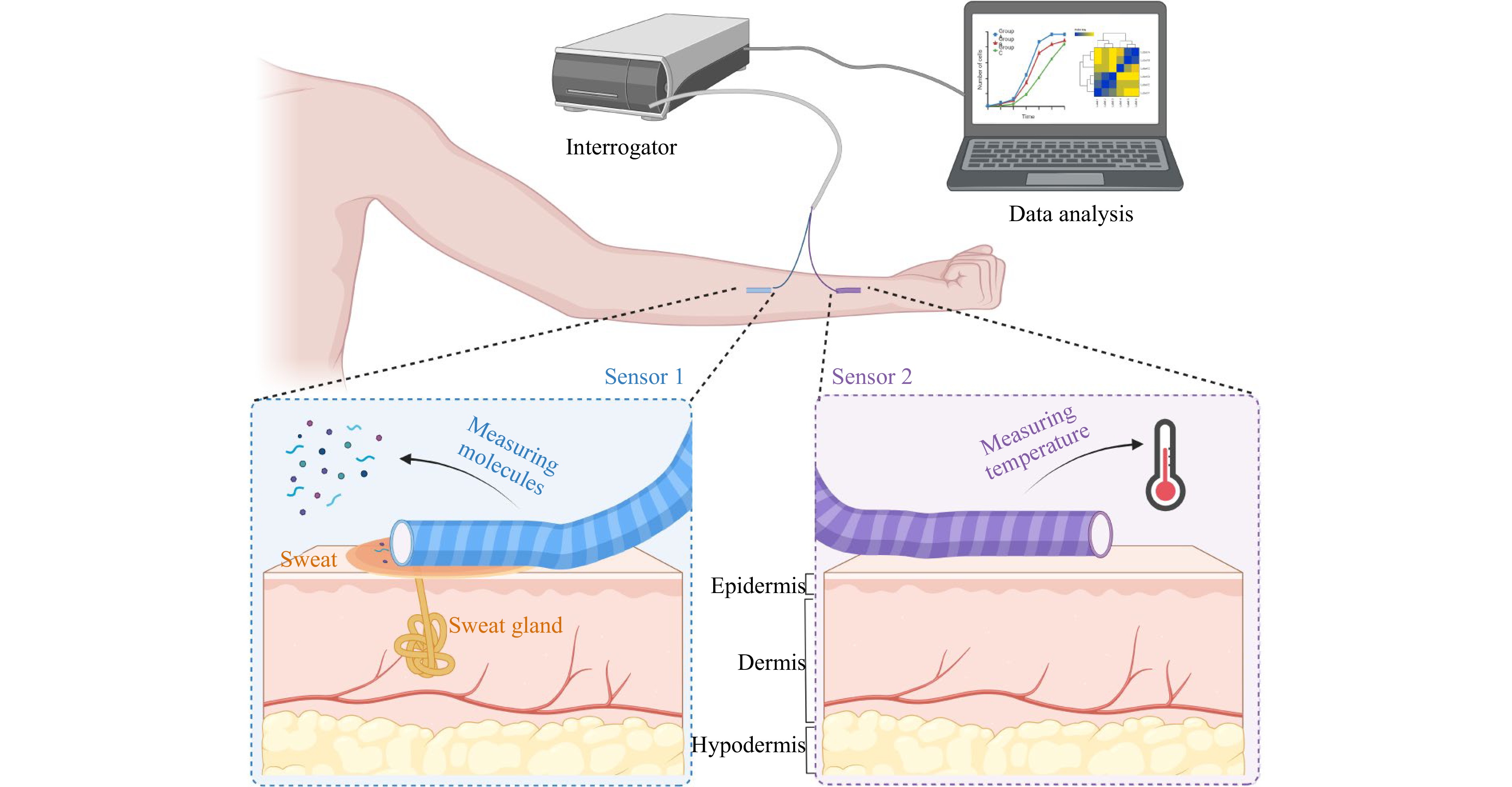

A change in scenario was recently reported by Fu et al. in their newly published paper in Light: Science & Applications24. The scope of this work, as displayed in Fig. 1, combines the measurement of physiological properties of the body with the interrogation of sweat biomarkers using a single optical fibre. To the best of our knowledge, this is the first study to demonstrate multi-parametric sensing with a single fibre for wearable devices.

Fig. 1 Illustration of a multi-parametric sensor for the dual measurement of sweat biomarkers and physiological properties of the skin.

The fibre proposed in this work was made of AST (As3Se5Te2) chalcogenide glass for operation in mid-infrared. After the drawing process, the fibre was tapered to increase the biomarker sensitivity. The sensing fibre was mounted on a wristband to monitor the evolution of sweat biomarkers (lactic acid, glucose, and urea) under static conditions and during physical exercise. The temperature change was measured using the wire resistance in the sensing zone, with a sensitivity of 5.84%/K.

Chalcogenide fibres can provide different perspectives for smart textiles and wearable devices. As described in a review by Lucas et al.25, these fibres operate at mid-infrared wavelengths and can achieve a penetration depth of up to several hundreds of nanometres for wavelengths up to 8 μm. However, the high propagation losses and difficulties in handling miniaturised hardware have thus far limited these types of fibres to bulky bio-chemical setups26, with the work of Fu et al. providing the first real case scenario of a wearable device operating at high speed.

While the measurement of body properties over the skin and related biomarkers has been dominated by electrode-based technologies to date, optical fibres now have the potential and maturity to provide substantial innovation in the field. Parallel opportunities offered by telecom-grade fibres (which are excellent for transmission and multiplexing), plastic fibres (which are highly stretchable and use the simplest hardware), and chalcogenide fibres (with high biological sensitivity) are likely to be exploited in the near future for next-generation photonic Internet-of-Things devices7,8,27.

Specialty optical-fibre sensors enable real-time contact measurement of multiple physiological parameters: towards all-fibre wearable devices

- Light: Advanced Manufacturing , Article number: (2025)

- Received: 12 May 2025

- Revised: 20 June 2025

- Accepted: 23 June 2025 Published online: 30 July 2025

doi: https://doi.org/10.37188/lam.2025.054

Abstract: The real-time measurements of surface physiological parameters, such as body temperature, cardiorespiratory rates, and sweat, is of increasing importance in healthcare. Optical fibres can offer an effective solution for contact sensing, as they enable multi-parameter and multi-point sensing while maintaining a compact form factor. Recent advances using chalcogenide and other specialty fibres represent a substantial step towards all-fibre wearable devices.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article′s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article′s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

DownLoad:

DownLoad: