-

Laser-assisted non-contact micro-transfer printing (μTP) has become an essential manufacturing approach in heterogeneously integrating microelectronic components1 on universal receivers for flexible electronics2,3 and micro-light-emitting diode (MicroLED) displays4. Specifically, laser irradiation through a transparent substrate induces localised interfacial reactions in a laser-sensitive layer and enables on-demand reduction of adhesion in the transfer stamp and subsequent release of microelectronic components5. However, despite sustained efforts to simultaneously increase transfer throughput and precision6,7, laser-chip misalignment remains a long-standing challenge, undermining reliability and hindering practical applications8. This challenge arises mainly from unavoidable intrinsic system errors, including scanning deviations, laser spot non-uniformity, stage vibrations, and thermal drift, which disrupt the synchronised release of the transferred devices and result in unpredictable flight trajectories (Fig. 1a)9, thereby substantially degrading transfer accuracy. Therefore, self-alignment during the transfer process is essential for high-precision microelectronics manufacturing.

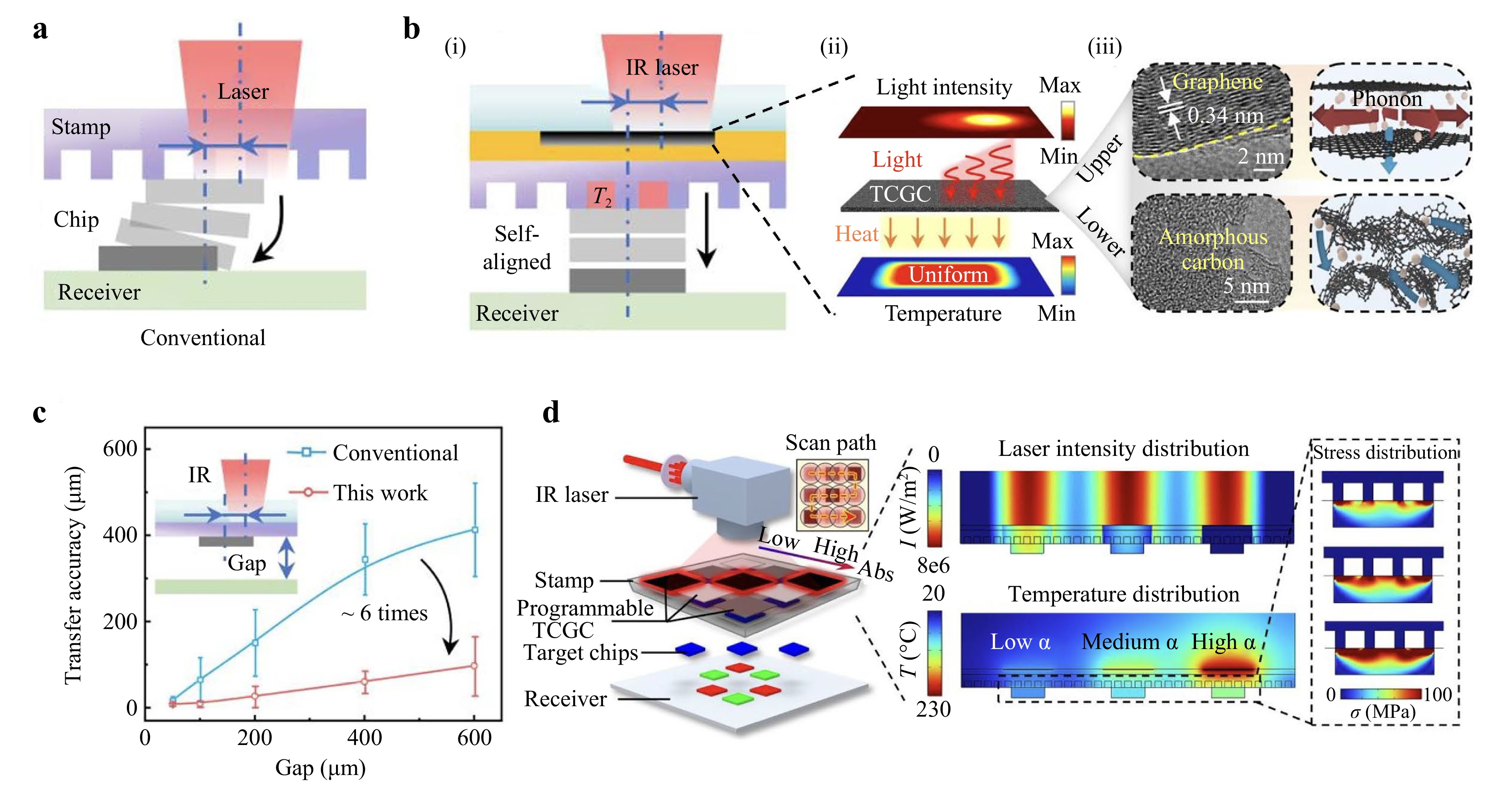

Fig. 1 Schematics illustrating a chip transfer errors resulting from laser irradiation deviations in conventional laser transfer processes and b TCGC-embedded stamp with (i) self-alignment due to (ii) homogenisation of asymmetric light irradiation into a uniform thermal output facilitated by TCGC. (iii) Structural composition of TCGC, consisting of an upper graphene layer with ordered atomic structure and high phonon transport efficiency and a lower amorphous carbon layer with disordered atomic structure and low phonon transport efficiency. c Comparison of chip transfer accuracy under offset IR laser irradiation for conventional approaches (without TCGC) and the proposed TCGC-based method. d Schematic diagram illustrating selective chip transfer through overall IR laser scanning.

Previous studies have typically focused on correcting the misalignment after asynchronous release and positional deviation have occurred, by using magnetic10 or fluidic aids11 to reposition the transferred microelectronic components. However, such methods fail to achieve a fundamentally synchronised release and significantly increase system costs and manufacturing complexity. Therefore, the more critical challenge for laser-assisted μTP is whether the energy-transfer pathway can be redesigned, rather than correcting misalignment post hoc, so that the system becomes intrinsically robust/insensitive to laser pointing errors while still achieving synchronised release. In a recently published paper on Light: Science & Applications, the self-aligned laser transfer (SALT) method12 offers an elegant and novel solution to this problem.

As illustrated in Fig. 1b, a thermal-conductivity-gradient carbon (TCGC) material embedded within the transfer stamp is introduced. Unlike conventional homogeneous photothermal layers, TCGC has a functional gradient structure formed by an upper high-thermal-conductivity graphene (Gr) layer and a lower low-thermal-conductivity amorphous carbon (AC) layer. The lower AC layer efficiently absorbs the laser energy and generates heat, whereas the upper Gr layer serves as a thermal interface that rapidly redistributes heat laterally, resulting in preferential in-plane thermal homogenisation. By guiding the heat flow rather than allowing unconstrained thermal diffusion, this design enables the nearly synchronous attainment of the delamination threshold temperature across all cavities, thereby fundamentally eliminating the transfer errors arising from out-of-sequence local releases. Directional photothermal regulation underpins this approach by relieving the strict dependence on precise laser irradiation paths, thereby imparting tolerance against small laser deviations. Consequently, the TCGC-assisted transfer exhibited substantially improved accuracy relative to conventional designs without TCGC, with an approximately six-fold enhancement maintained across different stamp-substrate gaps (Fig. 1c).

Notably, the fabrication of the TCGC layer is remarkably simple and relies on the excimer laser-induced, self-limited interfacial carbonisation of a polyimide film. This strategy builds on the authors’ earlier demonstrations of excimer laser-assisted manufacturing, in which the accumulated pulse number (APN) provided deterministic control over laser-polymer interactions and the resulting material transformations13. In the current process, APN serves as a deterministic control parameter, and increasing the APN progressively modulates the carbonisation depth and relative distribution of graphene and amorphous carbon, thereby tuning the infrared absorbance and photothermal conversion efficiency of the TCGC layer. This APN-defined photothermal programmability enabled spatially differentiated heating profiles, which allowed different cavities to reach the delamination threshold temperature in a prescribed sequence. Consequently, this approach naturally supports a sequential and programmable LED release, pointing toward scalable batch-mode transfer workflows (Fig. 1d).

Rather than enforcing perfect system conditions, this approach emphasises designing systems that are inherently tolerant to imperfections. In this context, programmable photothermal regulation enhances the stability and consistency of laser-assisted μTP in microelectronic manufacturing, thereby expanding its potential for practical processing applications. The broader significance of directional photothermal regulation may extend beyond improving the alignment tolerance in microtransfer printing. For example, in laser-based additive manufacturing, fluctuations in the beam profile or local heat accumulation often cause nonuniform melting and defects. By engineering photothermal energy redistribution at the material level, rather than relying solely on external precision, similar strategies can improve process robustness and manufacturability.

Gradient-graphene-enabled directional photothermal regulation for self-aligned laser transfer printing

- Light: Advanced Manufacturing , Article number: 18 (2026)

- Received: 22 December 2025

- Revised: 30 December 2025

- Accepted: 30 December 2025 Published online: 09 February 2026

doi: https://doi.org/10.37188/lam.2026.018

Abstract: Gradient-graphene-enabled directional photothermal regulation is proposed and demonstrated to achieve uniform heat distribution in the laser-sensitive layer, thereby enhancing the accuracy of self-aligned laser transfer printing.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article′s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article′s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

DownLoad:

DownLoad: