-

The Sun supplies approximately 120,000 terawatts of power to Earth, vastly surpassing the planet’s global consumption of 15 terawatts. Photovoltaics and solar thermoelectric generators (STEGs) are pivotal technologies that directly convert solar energy into electricity, presenting promising solutions to the global energy crisis and environmental challenges1,2. In contrast to photovoltaics, such as prevalent silicon-based cells limited to absorbing sunlight within the 300−1100 nm range, STEGs can capture the entire terrestrial solar spectrum (200−2500 nm)3,4. STEGs convert solar photon energy into heat, subsequently generating electricity through the Seebeck effect using thermoelectric semiconductors5,6.

The Seebeck effect is a fundamental thermoelectric phenomenon where a temperature gradient across a thermoelectric semiconductor induces an electric voltage. The performance of thermoelectric materials is typically assessed using the dimensionless figure of merit, ZT = (S2σ/k)T, where S denotes the Seebeck coefficient, σ indicates the electrical conductivity, k denotes the thermal conductivity (including contributions from electrons and lattice vibrations), and T represents the absolute temperature. STEGs are constructed by positioning a thermoelectric semiconductor between a solar absorber and a heat sink, thereby creating a temperature difference ΔT. The thermal-to-electrical conversion efficiency of a STEG, denoted as ηSTEG, is chiefly determined by the figure of merit ZT and the temperature difference (ΔT) between the hot side (Th) and cold side (Tc), as follows7:

$$ {{\eta }}_{STEG}=\frac{{T}_{h}-{T}_{c}}{{T}_{h}}\frac{\sqrt{1+ZT}-1}{\sqrt{1+ZT}+\dfrac{{T}_{c}}{{T}_{h}}} $$ Recently, substantial advancements have been made in enhancing the figure of merit ZT—either by increasing the power factor (S2σ) or by decreasing the lattice contribution to thermal conductivity κ—thereby improving STEG efficiency from a materials engineering standpoint8. Alternatively, for a constant ZT, the main approach to boost STEG efficiency is to maximise the temperature difference ΔT. This involves raising the hot-side temperature Th through effective solar energy absorption and minimising heat dissipation, as well as reducing the cold-side temperature Tc via efficient heat dissipation. However, achieving effective thermal management at both ends remains difficult, especially when using commonly employed metal-based materials.

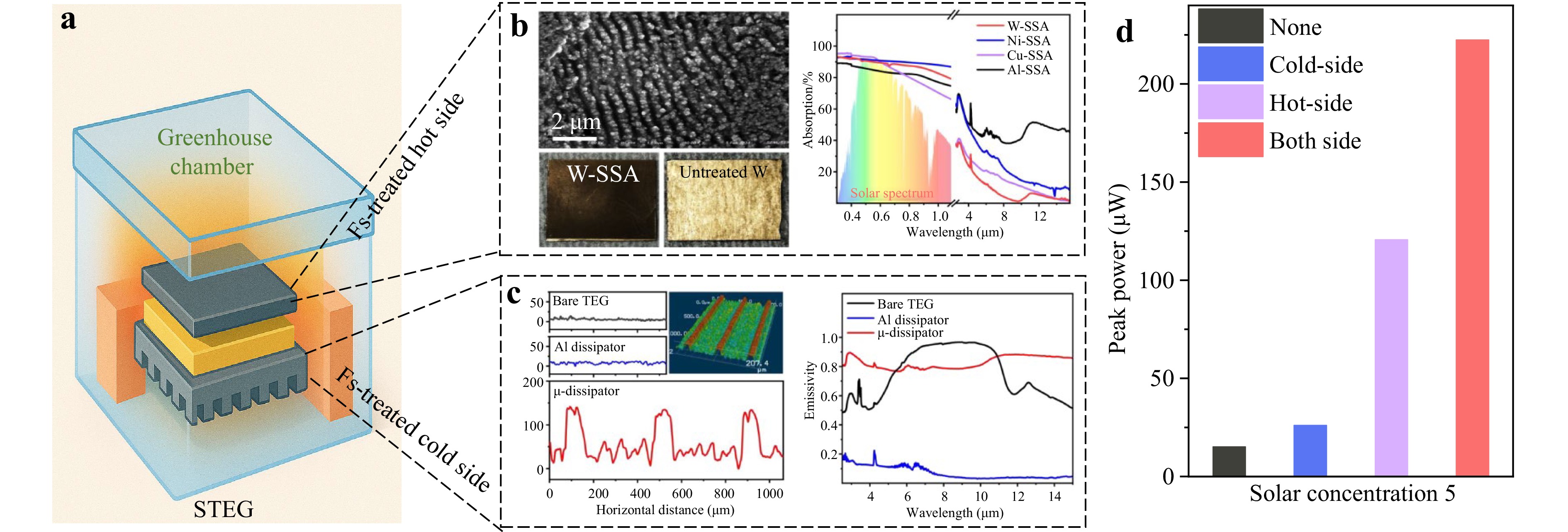

As reported in Light Science & Applications, Xu et al. developed a thermal management strategy that increased STEG power generation fifteenfold with only a 25% increase in weight by applying subtractive femtosecond (fs) laser treatment to metals at both the hot and cold ends (Fig. 1)9.

Fig. 1 Femtosecond (fs) laser treatment of the hot- and cold-end metals of a solar thermoelectric generator (STEG), enabling effective thermal management for enhanced power output. a Schematic illustration of the STEG device containing a greenhouse chamber on the hot side. b fs laser patterning of tungsten (W) metals at the hot end to increase visible-range absorptivity while reducing mid- and far-infrared range emissivity. c fs laser engravement of aluminium (Al) metals to create an Al μ-dissipator that significantly improves mid- and far-infrared emissivity. d Comparison of the peak power output of the STEG device under different thermal management configurations (hot side, cold side, both sides) versus the control (no thermal management) at 5-fold solar concentration.

At the hot end of an STEG, selective solar absorbers (SSAs) with high optical absorption in the short-wavelength solar spectrum (< 1000 nm) and low emissivity in the mid- to far-infrared range (> 4000 nm) are crucial for maximising solar energy capture while minimising radiative heat loss. The authors demonstrated that direct femtosecond laser processing of various metals, including nickel (Ni), copper (Cu), aluminium (Al), and tungsten (W), significantly alters both solar absorptance and infrared emissivity (Fig. 1b). Among these metals, tungsten (W) was chosen for its high melting point (3422 °C), exceptional mechanical strength, and configurable spectral properties.

By precisely controlling laser power, scanning speed, and interline spacing, optimised tungsten SSAs (W-SSAs) with tailored surface patterns were fabricated, transforming the untreated tungsten’s golden sheen into a black-like metallic lustre. The resulting laser-processed W-SSAs exhibited a solar spectrum-weighted absorptance of 0.9, approximately 1.5 times greater than untreated tungsten and three times higher than a bare TEG with a ceramic absorber (absorptance = 0.29). Notably, they maintained a low infrared emissivity (0.11) comparable to untreated tungsten. This exceptional spectral selectivity is attributed to femtosecond laser-induced surface nanostructures, which enhance light absorption through mechanisms such as surface plasmon resonance. The size and density of these nanostructures influence plasmonic resonance, and their ensembles broaden the spectral response, enabling customised absorption and emissivity profiles.

When the cold side of the STEG is naturally cooled via bulky metal fins, the spectral engineering of W-SSAs on the hot side significantly increases the temperature difference (ΔT). This results in approximately 7× and 2.7× enhancements in STEG peak power compared to the bare TEG (without SSAs) and a conventional tungsten absorber, respectively, across all solar concentrations. Additionally, a greenhouse chamber was constructed on the hot side using polyethylene stretch-tight food wrap, where trapped air serves as effective insulation, similar to bubble sheets, thereby reducing heat loss (Fig. 1a). The optimised 6-mm-thick air film achieved over a 40% reduction in convective and conductive thermal losses, boosting peak power by 1.5−1.7 times under varying solar concentrations (1 sun, 3 suns, and 5 suns). By combining fs laser-induced spectral engineering with the greenhouse chamber, solar absorption is maximised and radiative and convective losses are minimised, stabilising the hot end at elevated temperatures.

Bulky metal fins are typically used as heat sinks on the cold ends of STEGs to dissipate heat through convection. In contrast, an Al μ-dissipator was fabricated via fs laser treatment of aluminium (Al) and integrated into the STEG to enhance heat dissipation through both convection and radiation (Fig. 1c). Compared to a conventional Al surface, the Al μ-dissipator features hierarchical surface structures, where fs laser-written micro-grooves and micro-ridges are coated with nano- and microscale features. The optimised μ-dissipator incorporates grooves with a depth of 120 μm and a width of 320 μm, achieving approximately a 180% increase in effective surface area compared to a standard Al dissipator. Additionally, micro- and nanoscale structures fabricated through femtosecond laser processing enhance light absorption via surface plasmon resonance across a broad spectral range. This enhancement results in a ~7.2× increase in infrared emissivity relative to a standard Al dissipator, enabling roughly a 2× improvement in cooling performance and a 2.3× rise in STEG output power under identical ambient temperature conditions. The enhanced convective and radiative cooling capabilities of μ-dissipator render it suitable for both low- and high-temperature heat dissipation applications.

By implementing thermal management strategies on both the hot and cold sides—minimising heat losses on the hot side while augmenting radiative and convective cooling on the cold side—solar energy is captured and utilised more efficiently by the STEG. This optimisation creates a substantially larger temperature gradient across the device, achieving a 15× increase in output power with fivefold solar concentration while maintaining a compact form factor with only a 25% weight increase (Fig. 1d).

This study underscores the transformative potential of femtosecond laser treatment in significantly enhancing STEG system performance by maximising the temperature difference (ΔT) between the hot and cold ends. The precision of femtosecond laser processing allows for tailored modifications of the metallic surface properties at both ends, improving heat absorption, reducing heat loss, and increasing thermal-to-electric conversion efficiency. In this study, low-cost commercial bismuth telluride (Bi2Te3) thermoelectric semiconductors, typically exhibiting a low ZT of around 1 at room temperature (300 K) were utilized. . Laser-induced surface enhancements, in conjunction with high-ZT materials (~3)10, could fully exploit the potential of the STEG system, resulting in more efficient and sustainable solar energy solutions for real-world applications.

HTML

-

This work was supported by the Opening Project of State Key Laboratory of Space Power Sources (Grant No. YF07050123F2531), the Key Technology Research and Industrialization Demonstration Project of Qingdao (Grant No. 25-1-1-gjgg-1-gx), the Outstanding Young Scholars Project supported by the Natural Science Foundation of Heilongjiang Province, China (Grant No. JJ2023JQ0025), the grants from the National Natural Science Foundation of China (Grant No. 51972084, Grant No. 52272270), the Young Scientist Workshop (Harbin Institute of Technology) (Grant No. AUGA5710094420), and the Fundamental Research Funds for the Central Universities, China (Grant No. AUGA5710052614, Grant No. HIT.OCEF.2023041).

DownLoad:

DownLoad: