2022 Vol. 3, No. 1

Published. 2022, 3(1)

: 3-13

doi: 10.37188/lam.2022.005

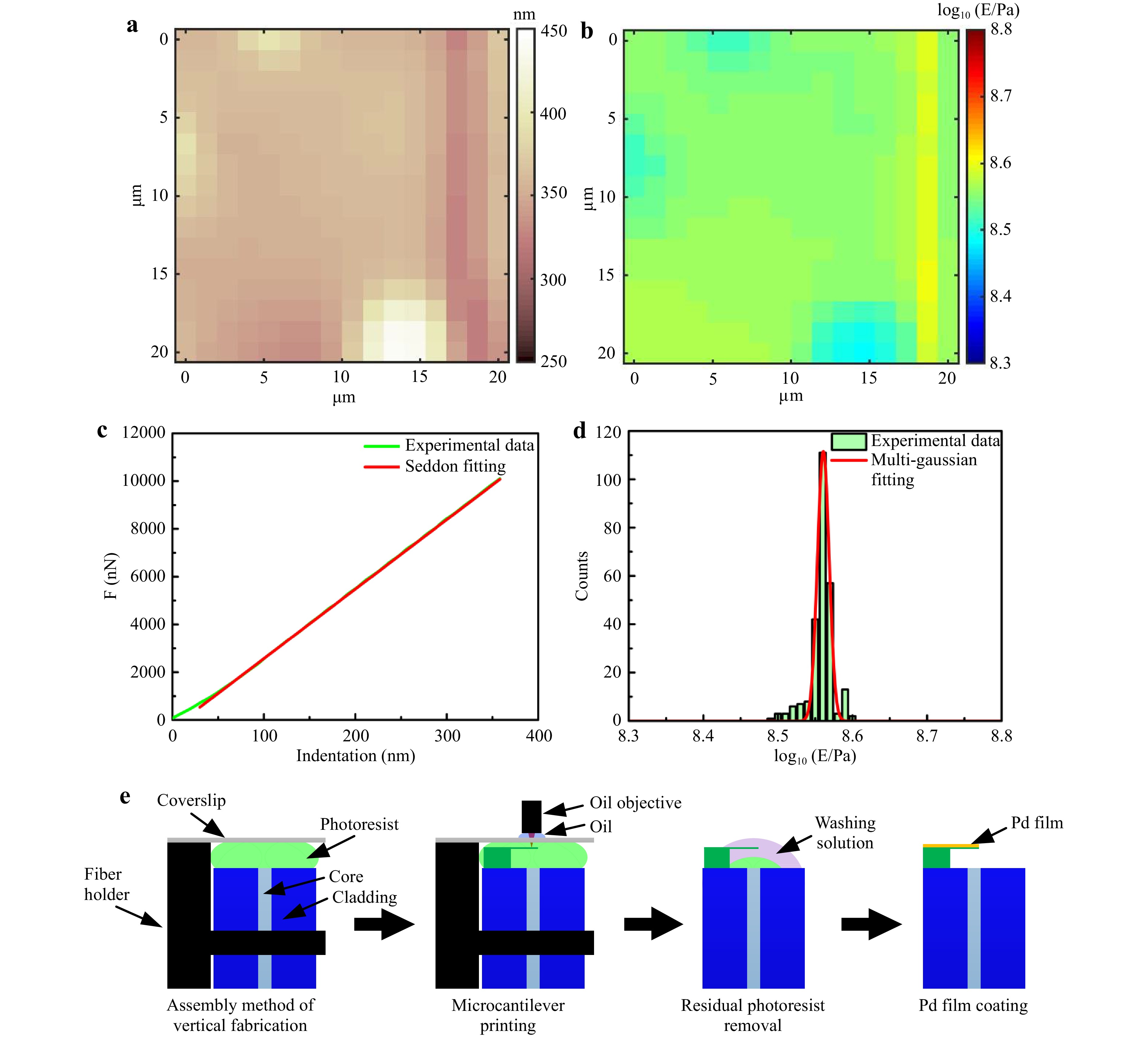

Cantilevers in microelectromechanical systems have the advantages of non-labeling, real-time detection, positioning, and specificity. Rectangular solid, rectangular hollow, and triangular microcantilevers were fabricated on an optical fiber tip via two-photon polymerization. The mechanical properties were characterized using finite element simulations. Coating the microcantilever with a palladium film enabled high sensitivity and rapid hydrogen detection. The shape of the cantilever determines the sensitivity, whereas the thickness of the palladium film determines the response time. Additional microelectromechanical systems can be realized via polymerization combined with optical fibers.

Published. 2022, 3(1)

: 14-25

doi: 10.37188/lam.2022.011

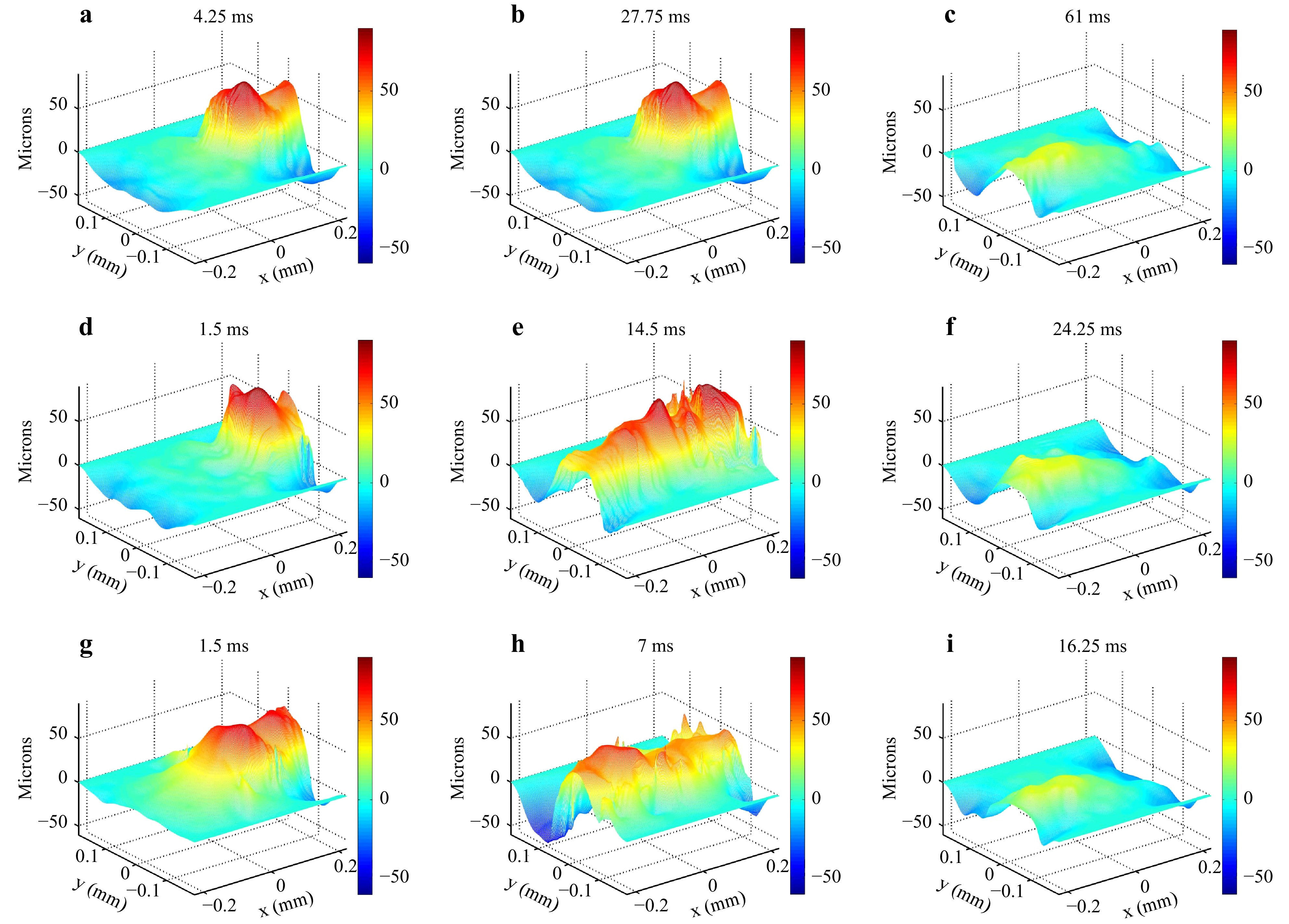

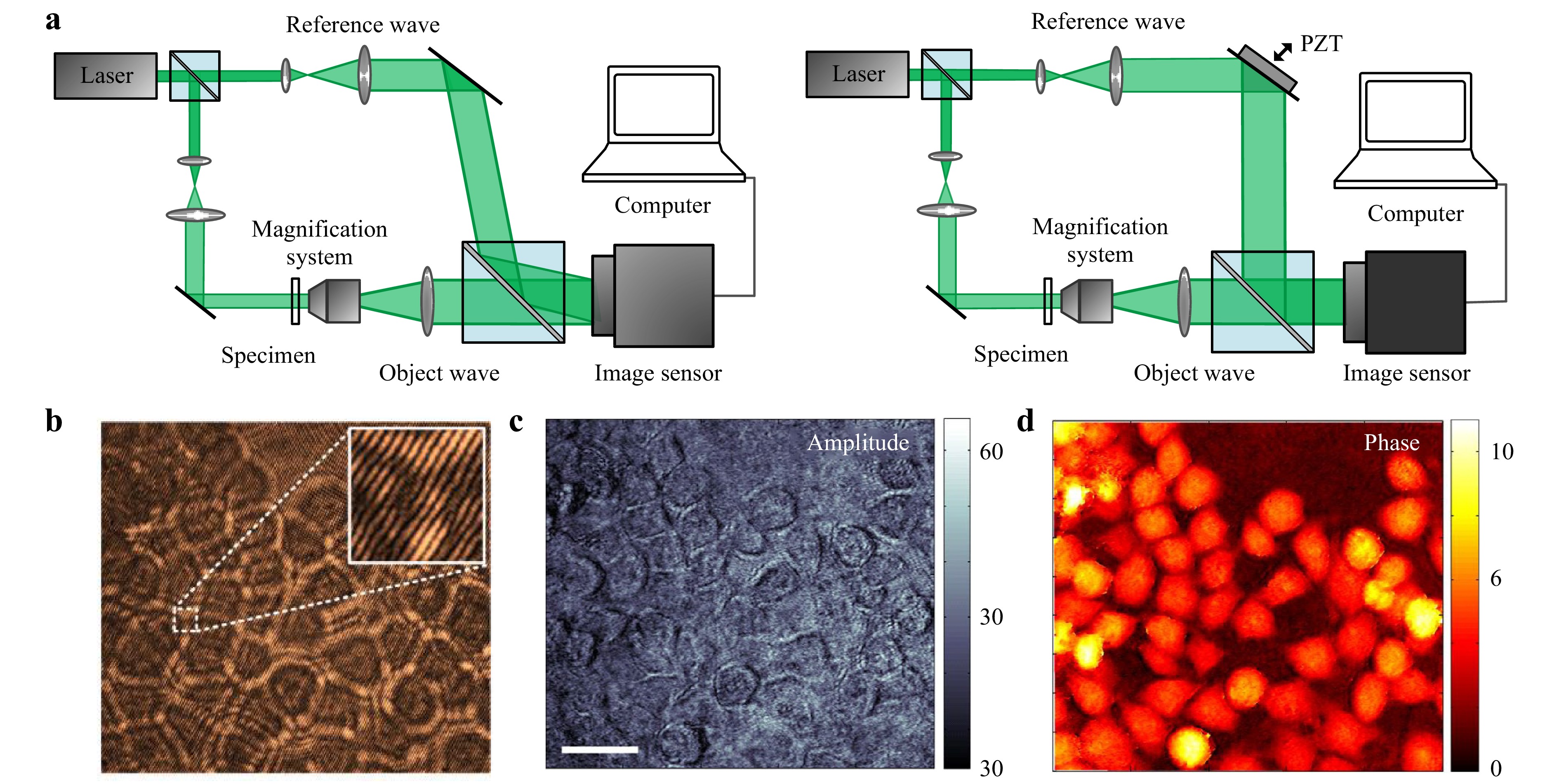

Over the past two decades, laser beam melting has emerged as the leading metal additive manufacturing process for producing small- and medium-size structures. However, a key obstacle for the application of this technique in industry is the lack of reliability and qualification mainly because of melt pool instabilities during the laser-powder interaction, which degrade the quality of the manufactured components. In this paper, we propose multi-wavelength digital holography as a proof of concept for in situ real-time investigation of the melt pool morphology. A two-wavelength digital holographic setup was co-axially implemented in a laser beam melting facility. The solidified aluminum tracks and melt pools during the manufacturing of 316L were obtained with full-field one-shot acquisitions at short exposure times and various scanning velocities. The evaluation of the complex coherence factor of digital holograms allowed the quality assessment of the phase reconstruction. The motion blur was analyzed by scanning the dynamic melt pool.

Holographic augmented reality display with conical holographic optical element for wide viewing zone

Published. 2022, 3(1)

: 26-34

doi: 10.37188/lam.2022.012

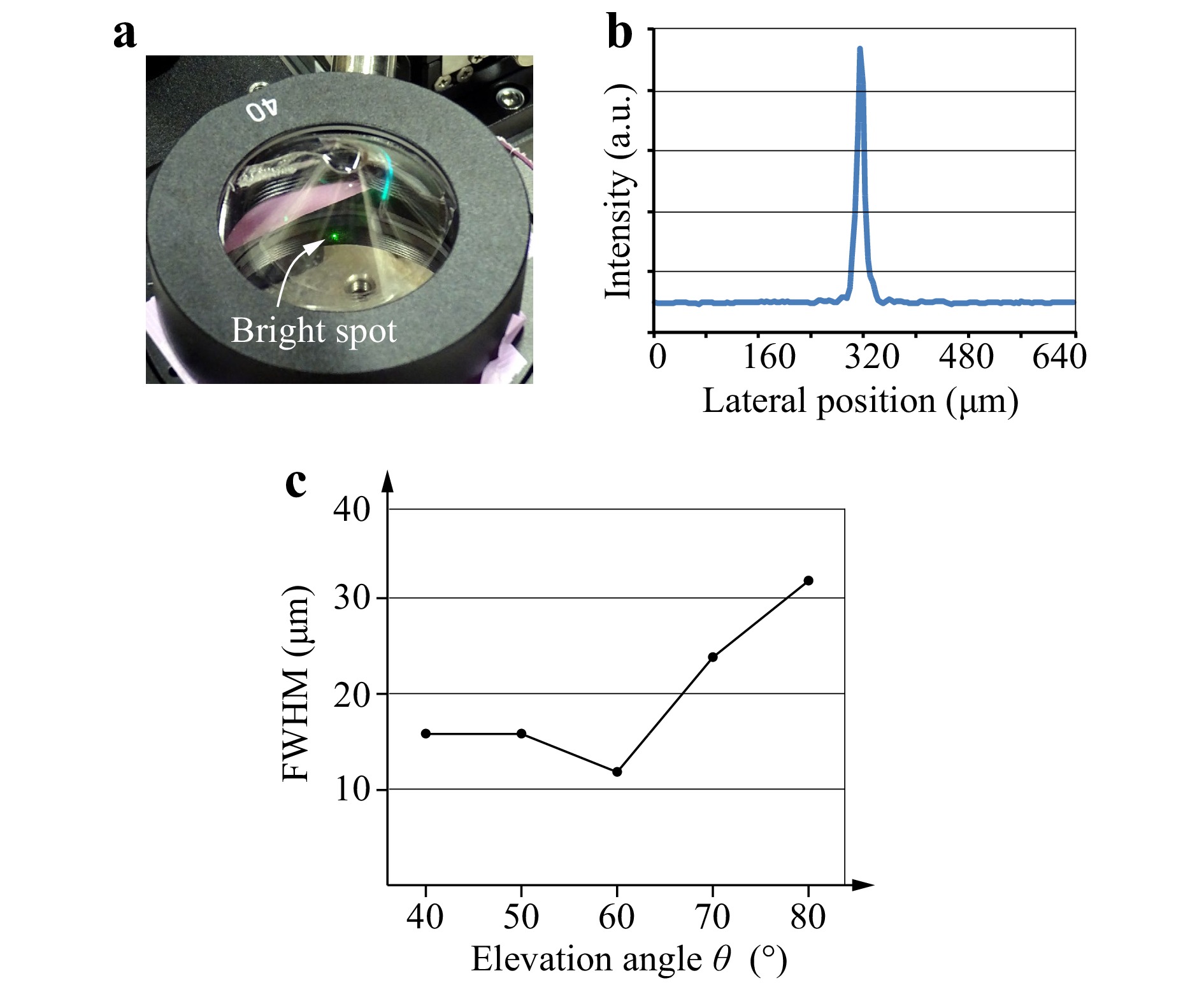

In this study, we propose a holographic augmented reality (AR) display with a wide viewing zone realized by using a special-designed reflective optical element. A conical holographic optical element (HOE) is used as such a reflective optical element. This conical HOE was implemented to reconstruct a diverging spherical wave with a wide spread angle. It has a sharp wavelength selectivity by recording it as a volume hologram, enabling augmented reality (AR) representation of real and virtual 3D objects. The quality of the generated spherical wave and the spectral reflectivity of the fabricated conical HOE were investigated. An optical superimposition between real and virtual 3D objects was demonstrated, thereby enhancing the validity of our proposed method. A horizontal viewing zone of 140° and a vertical viewing zone of 30° were experimentally confirmed. The fabrication procedure for the conical HOE is presented, and the calculation method of the computer-generated hologram (CGH) based on Fermat’s principle is explained in detail.

Published. 2022, 3(1)

: 35-64

doi: 10.37188/lam.2022.001

This paper presents the activities in the field of shearography in chronological order and highlights the great potential of this holographic measurement technology. After a brief introduction, the basic theory of shearography is presented. Shear devices, phase-shift arrangements, and multiplexed shearography systems are described. Finally, the application areas where shearography has been accepted and successfully used as a tool are presented.

Published. 2022, 3(1)

: 65-84

doi: 10.37188/lam.2022.003

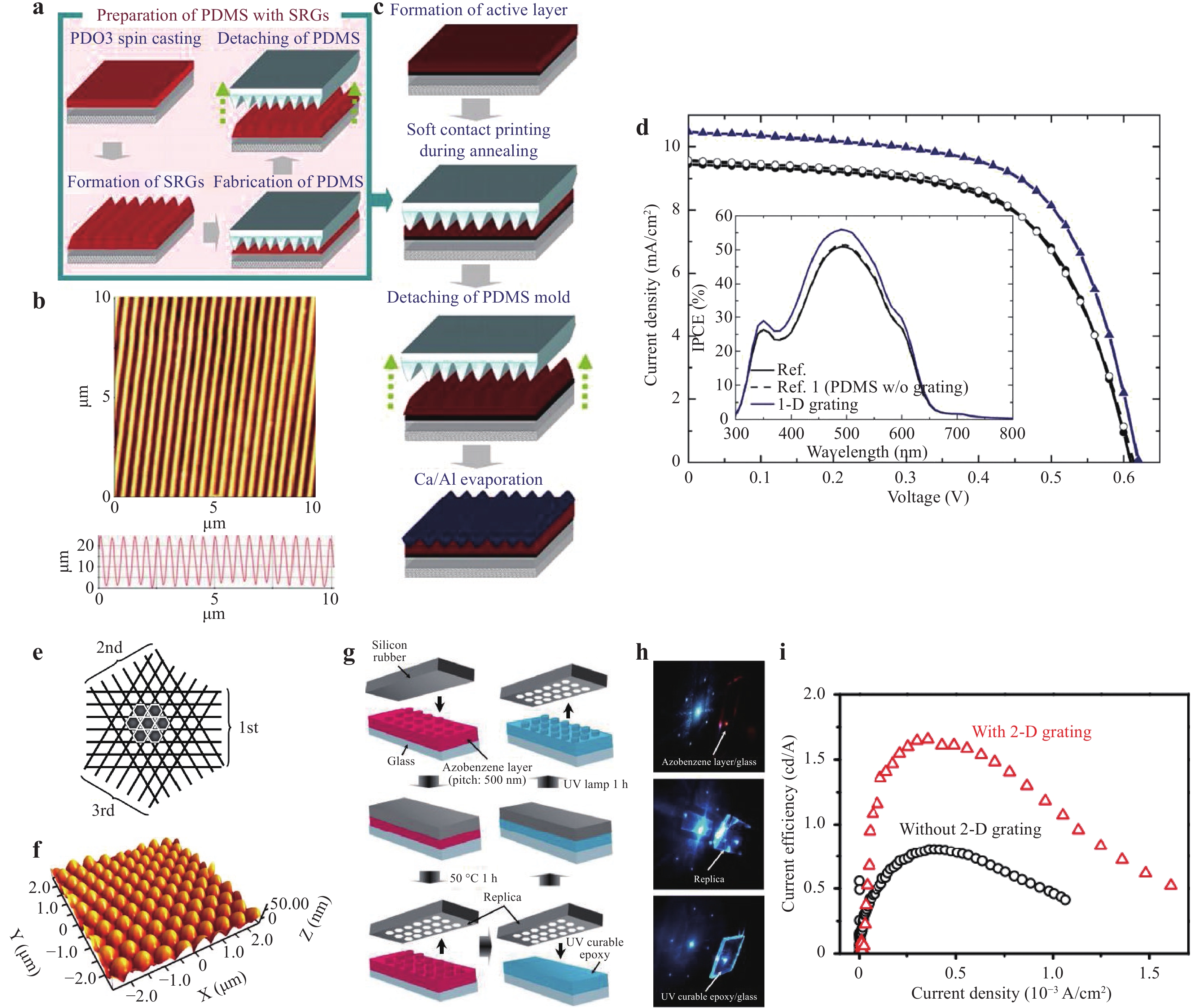

In current photo-based patterning techniques, an image is projected onto a photosensitive material to generate a pattern in the area where the light is focused. Thus, the size, shape, and periodicity of the pattern are determined by the features on the photomask or projected images, and the materials themselves generally do not play an active role in changing the features. In contrast, azobenzene polymers offer a unique type of photopatterning platform, where photoisomerization of the azobenzene groups can induce substantial material movements at the molecular, micro-, and macroscales. Stable surface relief patterns can be generated by exposure to interference light beams. Thus, periodic nano- and microstructures can be fabricated with both two- and three-dimensional spatial control over a large area in a remarkably simple way. Polarized light can be used to guide the flow of solid azobenzene polymers along the direction of light polarization via an unusual solid-to-liquid transition, allowing for the fabrication of complex structures using light. This review summarizes the recent progress in advanced manufacturing using azobenzene polymers. This includes a brief introduction of the intriguing optical behaviors of azobenzene polymers, followed by discussions of the recent developments and successful applications of azobenzene polymers, especially in micro- and nanofabrication.

Published. 2022, 3(1)

: 85-104

doi: 10.37188/lam.2022.004

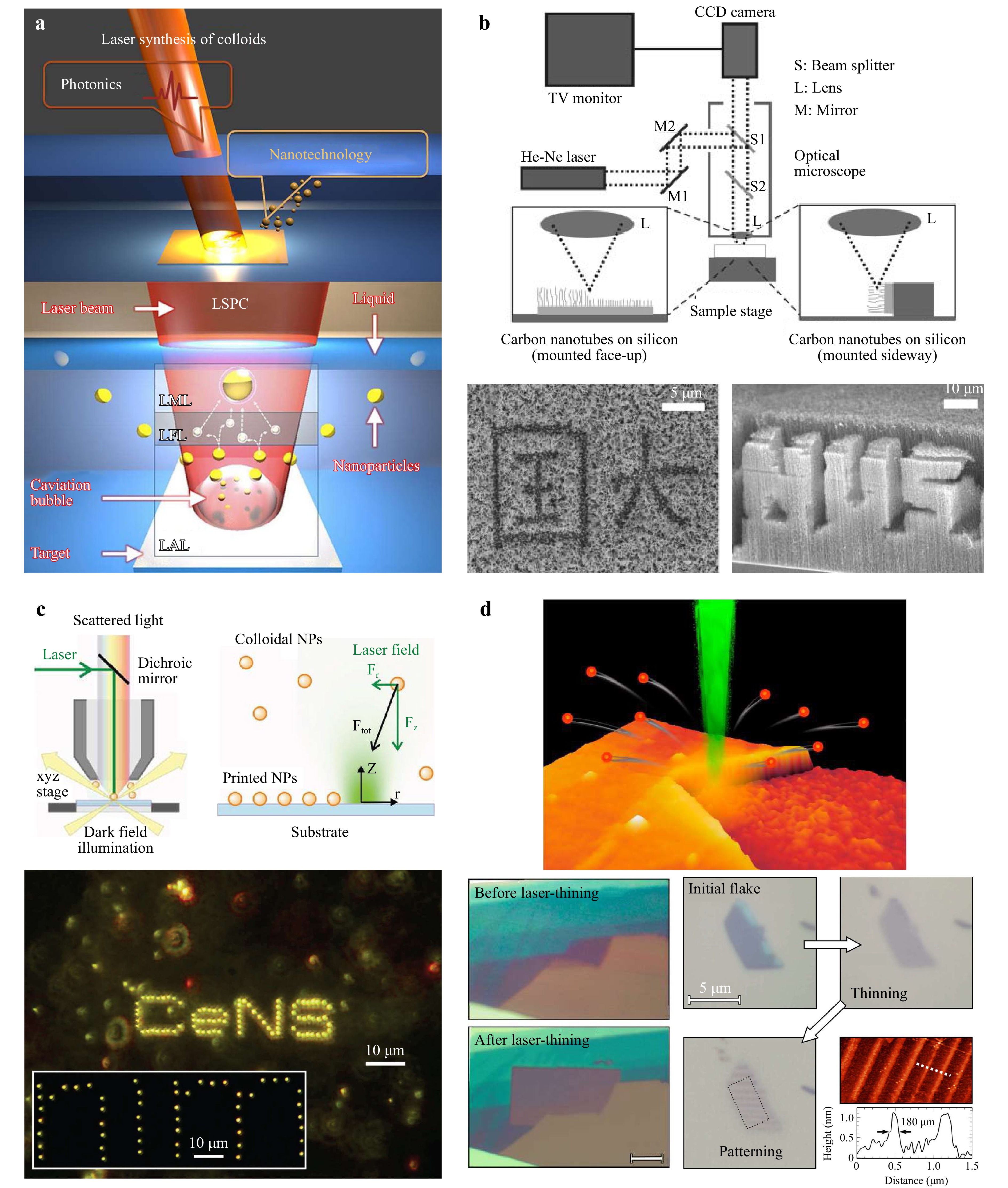

Fluorescent nanomaterials have long been recognized as essential contributors to the advancement of material technologies. Over the years, the rapid expansion in this massive selection of materials has led to the emergence of systems with tunable and unique fluorescent properties, occupying pivotal roles across niche areas in imaging, photonics, micro-encryption, and steganographic applications. In recent years, research interest in the translation of laser-based operations towards the production and modulation of nanomaterial fluorescence has been reignited, owing to its ease of operation and low cost. In this paper, we summarize the assortment of laser operations for the fabrication, modification, and spatial positioning of various fluorescent nanomaterials, ranging from metallic nanoparticles, carbon dots, 2D ultrathin films to wide-bandgap nanomaterials, and upconversion nanocrystals. In addition, we evaluate the importance of laser-modified fluorescence for various applications and offer our perspective on the role of laser-based techniques in the forthcoming advancement of nanomaterials.

Published. 2022, 3(1)

: 105-120

doi: 10.37188/lam.2022.006

Digital holographic microscopy (DHM), which combines digital holography with optical microscopy, is a wide field, minimally invasive quantitative phase microscopy (QPM) approach for measuring the 3D shape or the inner structure of transparent and translucent samples. However, limited by diffraction, the spatial resolution of conventional DHM is relatively low and incompatible with a wide field of view (FOV) owing to the spatial bandwidth product (SBP) limit of the imaging systems. During the past decades, many efforts have been made to enhance the spatial resolution of DHM while preserving a large FOV by trading with unused degrees of freedom. Illumination modulation techniques, such as oblique illumination, structured illumination, and speckle illumination, can enhance the resolution by adding more high-frequency information to the recording system. Resolution enhancement is also achieved by extrapolation of a hologram or by synthesizing a larger hologram by scanning the sample, the camera, or inserting a diffraction grating between the sample and the camera. For on-chip DHM, spatial resolution is achieved using pixel super-resolution techniques. In this paper, we review various resolution enhancement approaches in DHM and discuss the advantages and disadvantages of these approaches. It is our hope that this review will contribute to advancements in DHM and its practical applications in many fields.

Published. 2022, 3(1)

: 121-136

doi: 10.37188/lam.2022.008

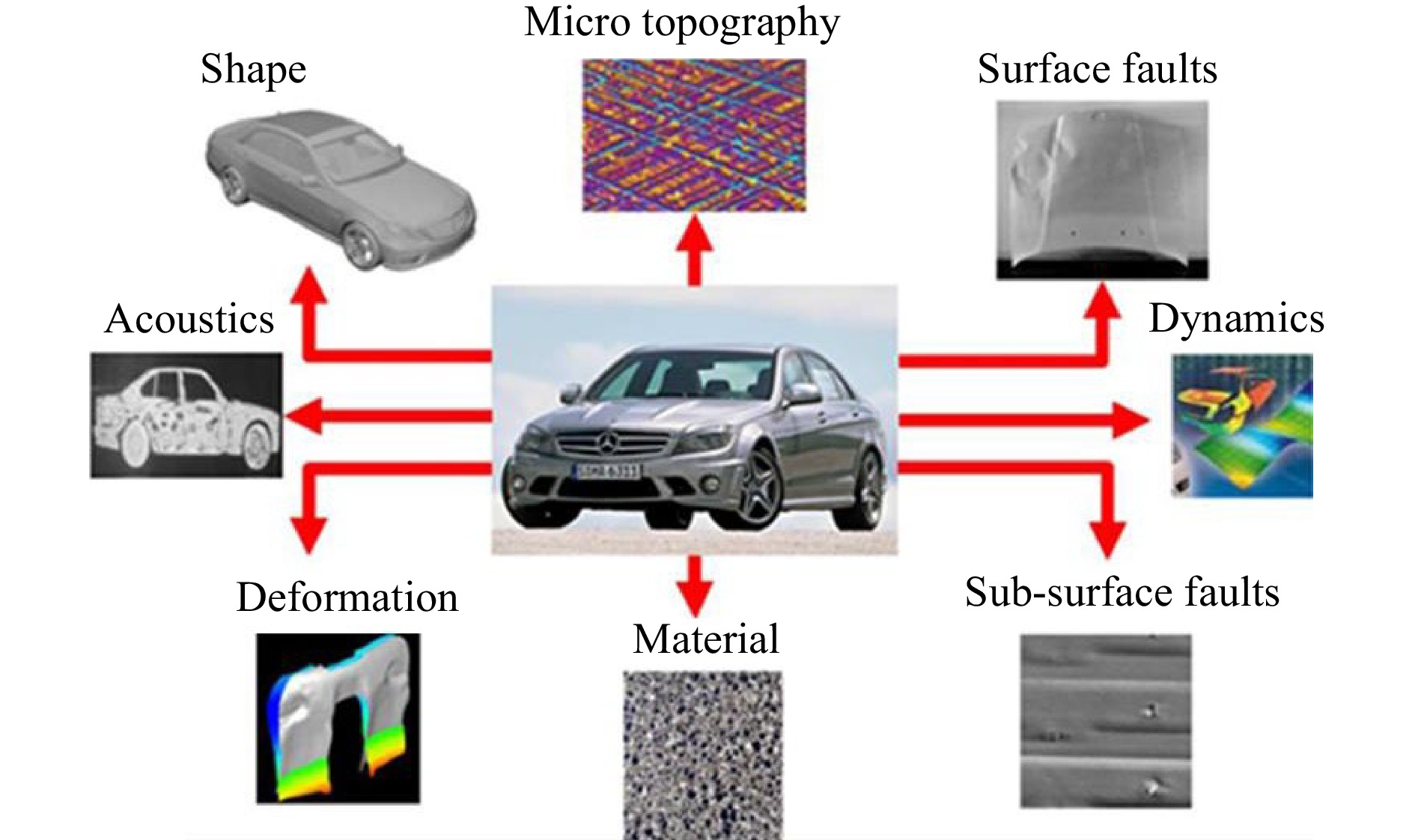

Holographic methods for non-destructive testing, shape measurement, and experimental stress analysis have shown to be versatile tools for the solution of many inspection problems. Their main advantages are the non-contact nature, the non-destructive and areal working principle, the fast response, high sensitivity, resolution and precision. In contrast to conventional optical techniques such as classical interferometry, the holographic principle of wavefront storage and reconstruction makes it possible to investigate objects with rough surfaces. Consequently, the response of various classes of products on operational or artificial load can be examined very elegantly. The paper looks back to the history of holographic metrology, honors the inventors of the main principles, discusses criteria for the selection of a proper inspection method, and shows exemplary applications. However, the main focus is on modern developments that are inspired by the rapid technological process in sensing technology and digitization, on current applications and future challenges.

Published. 2022, 3(1)

: 137-150

doi: 10.37188/lam.2022.009

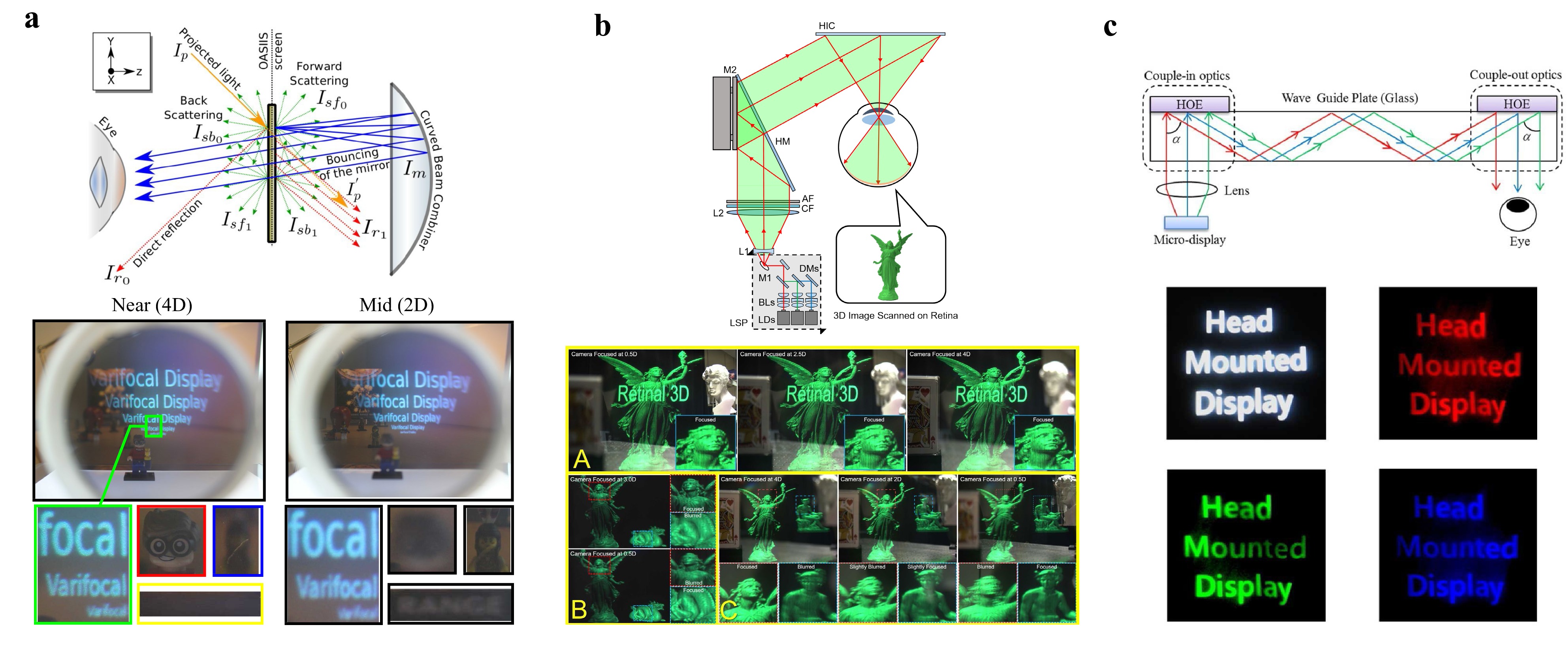

Near-eye displays are the main platform devices for many augmented reality (AR) and virtual reality (VR) applications. As a wearable device, a near-eye display should have a compact form factor and be lightweight. Furthermore, a large field of view and sufficient eyebox are crucial for immersive viewing conditions. Natural three-dimensional (3D) image presentation with proper focus cues is another requirement that enables a comfortable viewing experience and natural user interaction. Finally, in the case of AR, the device should allow for an optical see-through view of the real world. Conventional bulk optics and two-dimensional display panels exhibit clear limitations when implementing these requirements. Holographic techniques have been applied to near-eye displays in various aspects to overcome the limitations of conventional optics. The wavefront reconstruction capability of holographic techniques has been extensively exploited to develop optical see-through 3D holographic near-eye displays of glass-like form factors. In this article, the application of holographic techniques to AR and VR near-eye displays is reviewed. Various applications are introduced, such as static holographic optical components and dynamic holographic display devices. Current issues and recent progress are also reviewed, providing a comprehensive overview of holographic techniques that are applied to AR and VR near-eye displays.

Published. 2022, 3(1)

: 151-176

doi: 10.37188/lam.2022.010

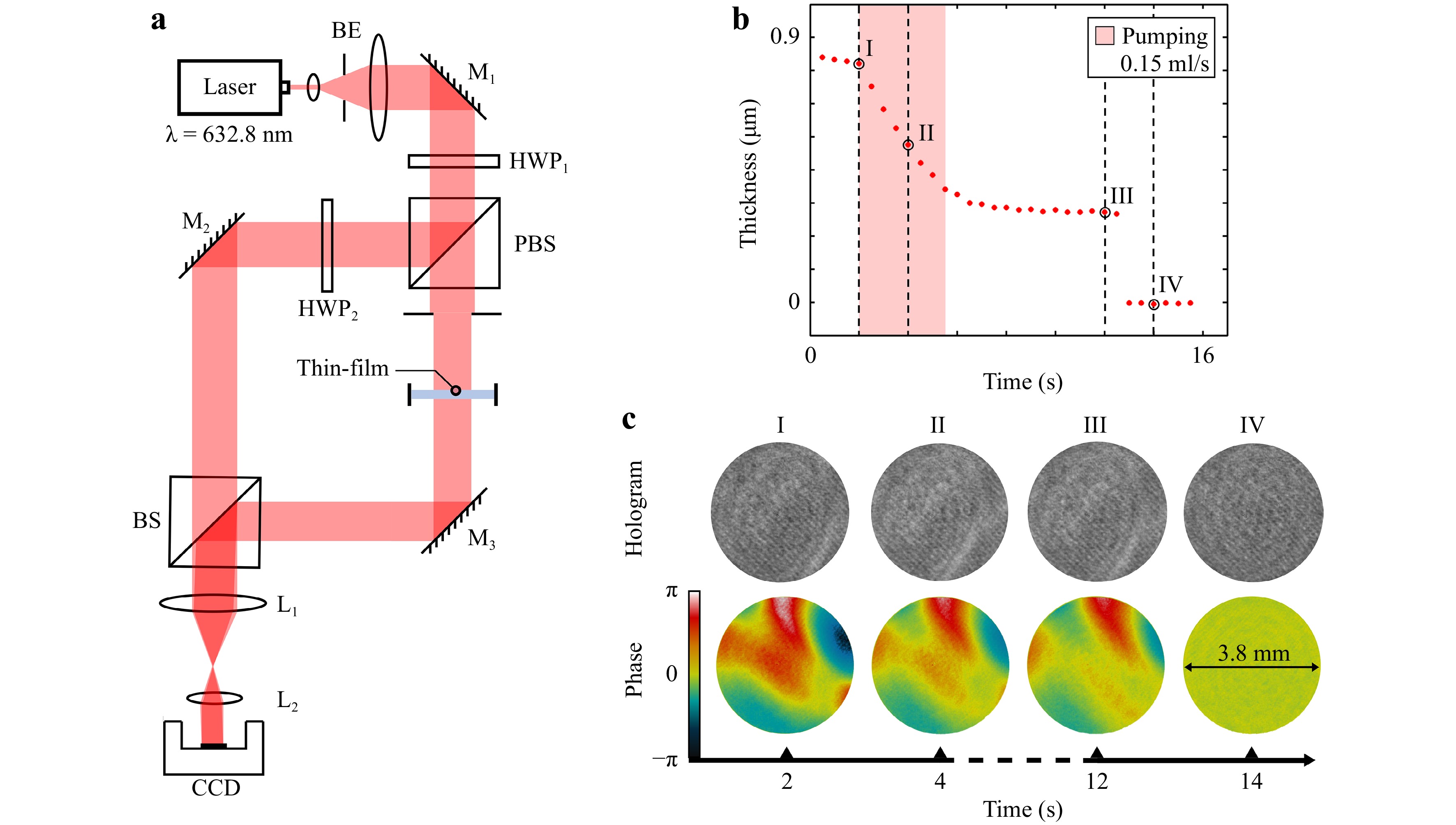

The appearance of the first laser approximately 12 years after the invention of holography by Gabor (1948) revolutionized the field of optical metrology. In fact, the invention of holographic interferometry enabled the exploitation of interferometry on non-mirror surfaces and full-scale objects. The holography-based measurement methods has been implemented to several industrial systems or in support of R&D with the aim of improving new products in many fields (automotive, aerospace, electronics, etc.). To date, holography has been considered an important measurement tool for non-destructive inspection (NDI), strain-stress measurement, and vibration analysis at various engineering sites. Recently, the new paradigm of Industry4.0 has seen the introduction of new technologies and methods of processing materials as well as the development of manufacturing approaches for the realization of innovative products. For example, direct printing, additive, and bottom-up manufacturing processes are expected to involve new ways of making products in future, and most innovative fabrication processes will be based on the manipulation of soft matter (e.g., starting from the liquid phase) that will be shaped at the nanoscale. The inherent characteristics of digital holography (DH) make it a powerful and accurate tool for the visualization and testing of final products, as well as for in situ and real-time monitoring and quantitative characterization of the processes involved during the fabrication cycle. This review aims to report on the most useful applications of soft matter, where the capabilities offered by DH, such as three-dimensional (3D) imaging, extended focus, 3D tracking, full-field analysis, high sensitivity, and a wide range of measurements from nanometers to centimeters, permit completely non-invasive characterizations on a full-scale. Several holographic experimental results of typical samples are reported and discussed where DH plays a primary role as a tool gauge for soft matter.

Email

Email RSS

RSS