View by Category

Published

, Published online: 27 October 2025

, doi: 10.37188/lam.2025.075

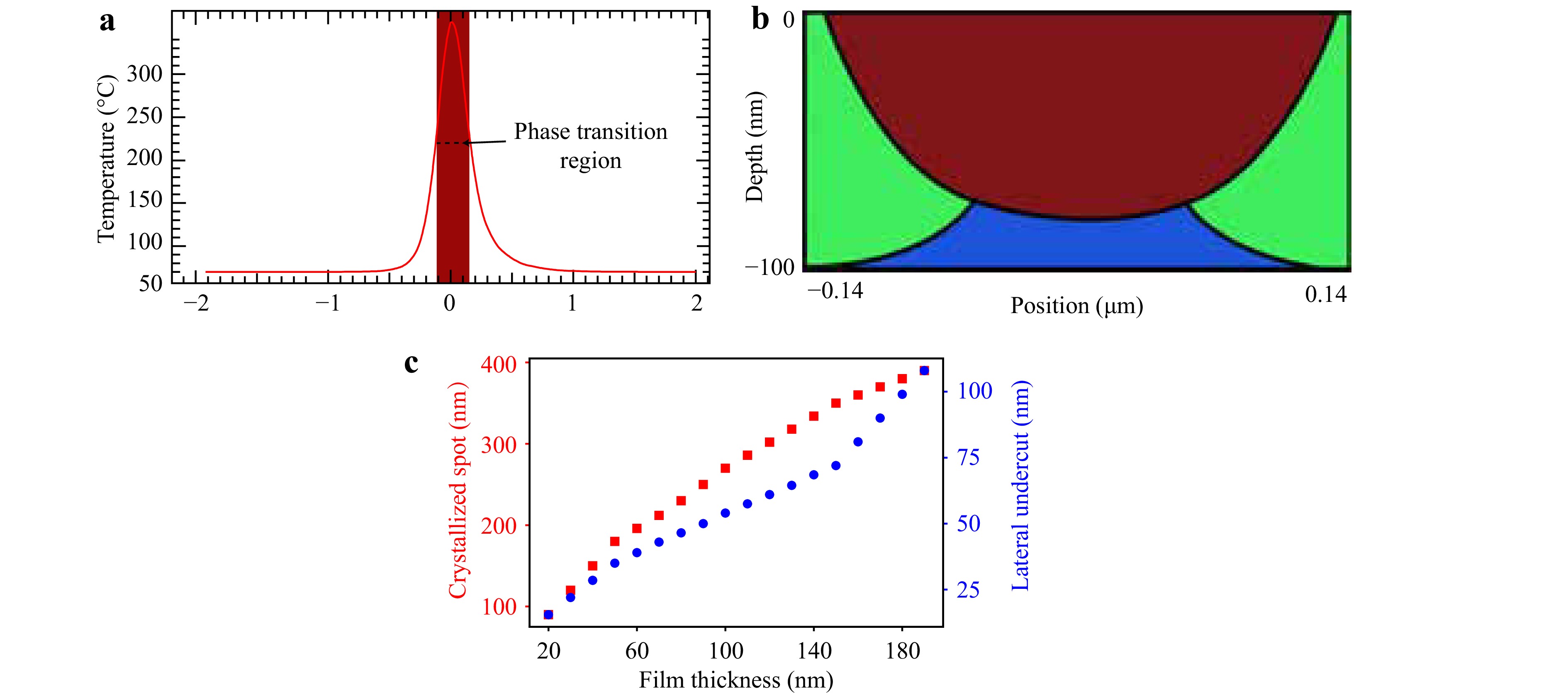

Modern technologies have been heavily reliant on semiconductor chips driving their innovation. These nanoscale-featured devices have created the need for precise lithographic tools that enable the microscopic patterning of such features. With a large drive to keep the cost of lithography tools low while maintaining high resolution, recent works have explored alternate solutions to existing commercial tools. Therefore, this study investigates a low-cost photothermal lithography technique that utilizes a phase-change material to allow for high-resolution 200 nm features to be patterned. The technique we present in this work does not only provide a sidewall roughness of < 10 nm but also uses light-insensitive materials, allowing for delicate features to be patterned under non-restrictive environments. We present the theoretical limits of our laser writing system and demonstrate the experimentally achieved features, describing in detail how we overcome some of the diffraction and thermal limits in order to achieve ultimate resolution and sidewall roughness. This was achieved with near 100% yield as every patterned feature survived all stages of the sample processing with minimal defects.

Published

, Published online: 29 January 2026

, doi: 10.37188/lam.2026.003

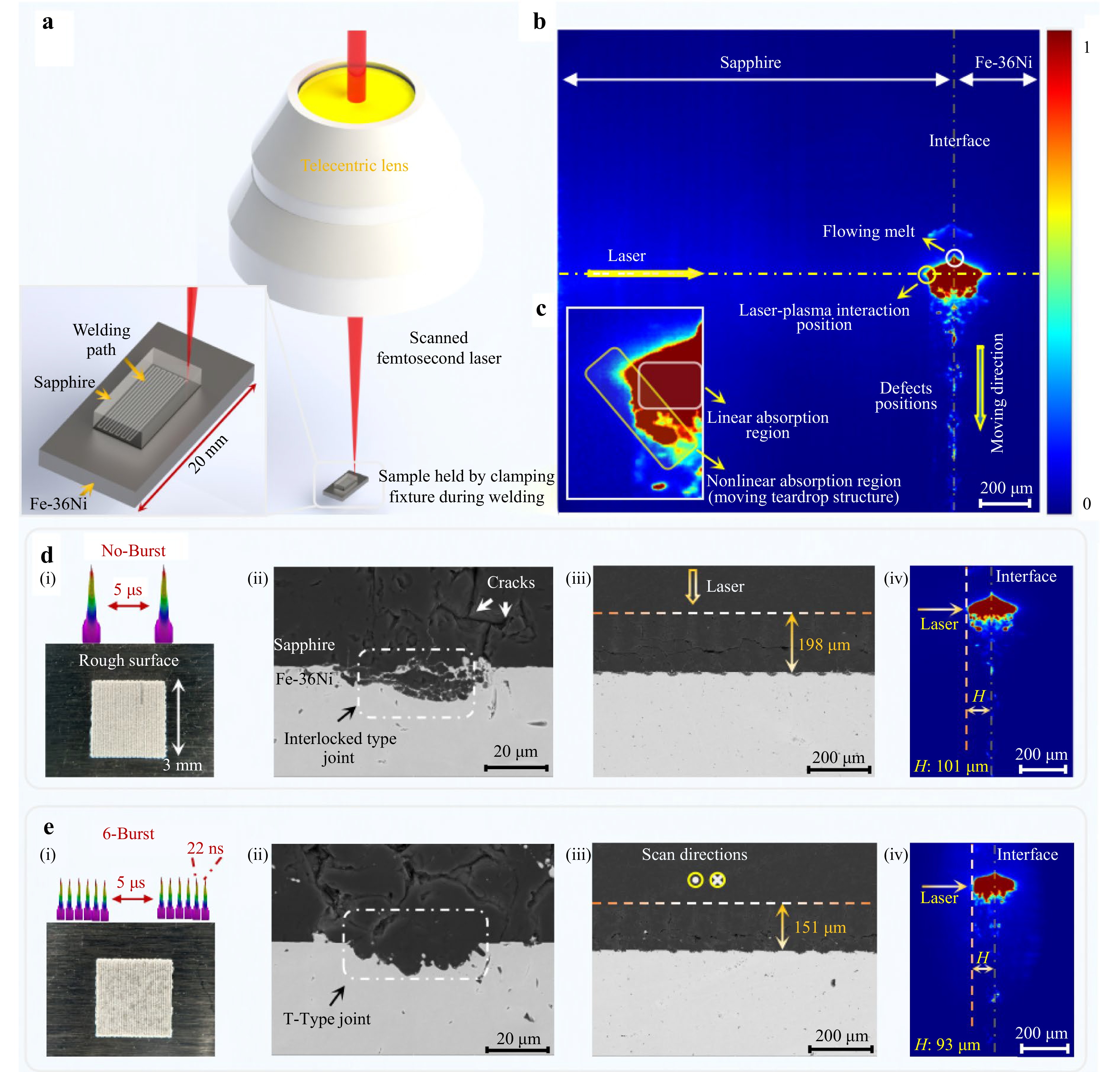

Abstract. The efficient and robust joining of transparent metal-dissimilar materials remains a significant challenge in high-performance system integration. A primary barrier is the inherently rough surfaces of metals, which hinder reliable bonding with transparent materials, largely due to the limited understanding of the underlying welding mechanisms. In this study, we demonstrate ultrafast laser joining between sapphire and metal substrates with surface roughness (Sa) up to 2 μm, achieving a maximum shear strength of 11.73 MPa. High-speed imaging techniques were employed to conduct the first systematic investigation of coupled absorption dynamics at heterogeneous interfaces. The plasma ejection observed during welding indicated that the molten metal actively confined the interfacial region, transforming the initial free space into a confined space. This transition facilitates the formation of an optical contact condition, significantly improving the joint strength. To further explore the potential of pulse shaping in controlling interfacial behaviour, the effects of temporal shaping (Burst mode) on laser energy deposition, joint strength, and interfacial morphology were examined. Consistent joint quality was achieved across a range of burst parameters, with shear strengths ranging from 9 to 13 MPa. Fractographic analysis indicated that the fracture was predominantly governed by the internal stress within the sapphire, thereby limiting further improvements in joint strength. The revelation of the ultrafast laser welding mechanism for non-optical contact dissimilar materials, along with the exploration of temporal shaping for enhancing welding performance, offers theoretical insights and technical guidance for the development of high-performance heterogeneous material joining.

Published

, Published online: 12 January 2026

, doi: 10.37188/lam.2026.002

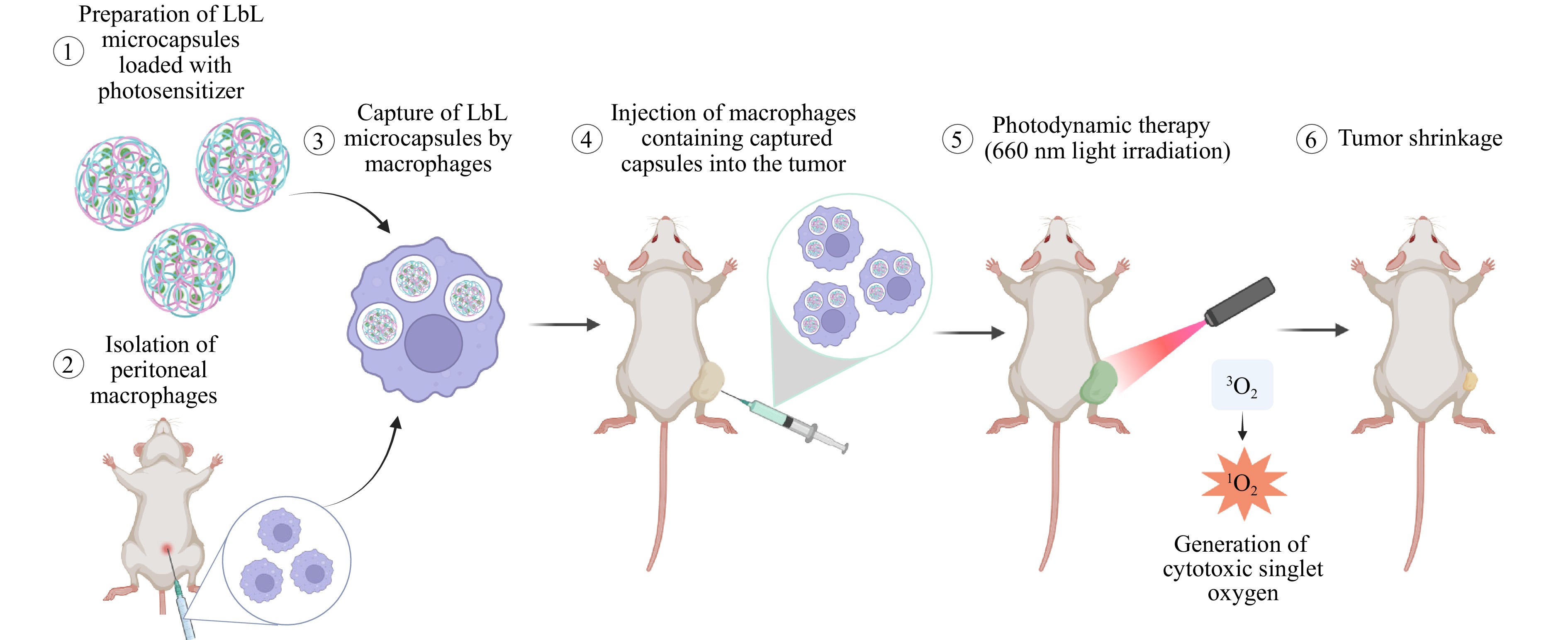

Photodynamic therapy (PDT) is a promising strategy for treating solid tumours due to its spatially controlled, light-triggered cytotoxicity. Although recent advances in optical technologies have improved light delivery, PDT efficacy remains limited by insufficient drug accumulation in tumours, largely due to the complexity of the tumour microenvironment. To address this challenge, a macrophage-mediated delivery platform was developed using layer-by-layer (LbL) microcapsules loaded with second-generation photosensitizers: photoditazine (PD) and aluminum tetrasulfophthalocyanine chloride (PS). Both photosensitizers exhibited low dark toxicity and high phototoxicity, enabling their safe transport by carrier cells. The photosensitizers were efficiently encapsulated into LbL microcapsules (6.2 ± 0.5 μm) with different shell compositions. Significant differences were observed between macrophage types: RAW 264.7 macrophages predominantly retained capsules on the cell surface, whereas primary peritoneal macrophages (PMs) internalised capsules within 3 h and retained them for up to 6 d without degradation. Among the tested formulations, polyarginine/dextran sulfate ((PArg/DS)4) capsules loaded with PD demonstrated the highest uptake efficiency and supported macrophage migration into tumour spheroids. In vivo experiments using a CT-26 colon cancer model confirmed the therapeutic potential of this platform, while highlighting the need for further optimisation for large tumours. This study provides new insights into cell-mediated delivery systems and underscores their potential to enhance PDT outcomes beyond current limitations.

Published

, Published online: 09 December 2025

, doi: 10.37188/lam.2025.076

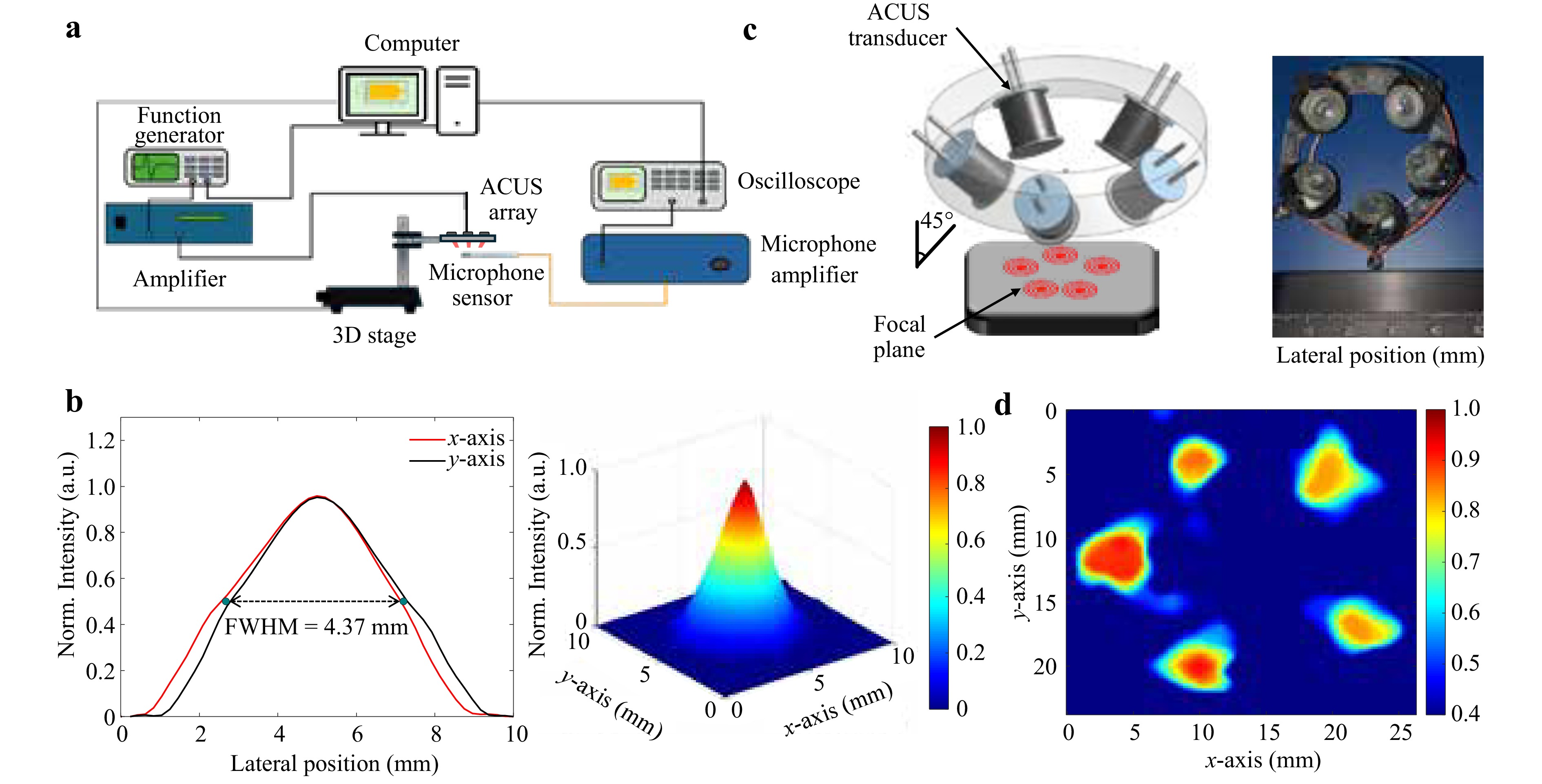

Reverberant optical coherence elastography (Rev-OCE) has been used to map the mechanical properties of tissues with high quality and resolution regardless of tissue boundaries and stiffness. Generally, Rev-OCE utilizes the interference of multiple arbitrary mechanical waves generated by distinct sources in direct contact with the sample. In this study, a novel methodology was designed and implemented to create a completely noncontact method utilizing multiple air-coupled ultrasound (ACUS) transducers capable of generating a reverberant field within the sample. An array of unfocused ACUS transducers with a resonant frequency of 40 kHz was characterized and placed in a 3D-printed ring to produce a reverberant field in a side-by-side gelatin phantom (4% and 8% w/w gelatin concentration). The results showed the generation of a reverberant field within the sample with a transverse resolution of 208.8 ± 72.4 μm. Also, this method was tested in porcine cornea showing the stiffness differences found in the corneal layers, where the wave speed is substantially higher in the epithelium (3.7 m/s) and anterior stroma regions compared with the posterior and endothelium regions (2.2 m/s). The generation of a reverberant field using ACUS Rev-OCE guarantees the integrity of sensitive samples, and it shows its potential to be used in-vivo without causing any damage or discomfort in live subjects.

Published

, Published online: 27 November 2025

, doi: 10.37188/lam.2025.077

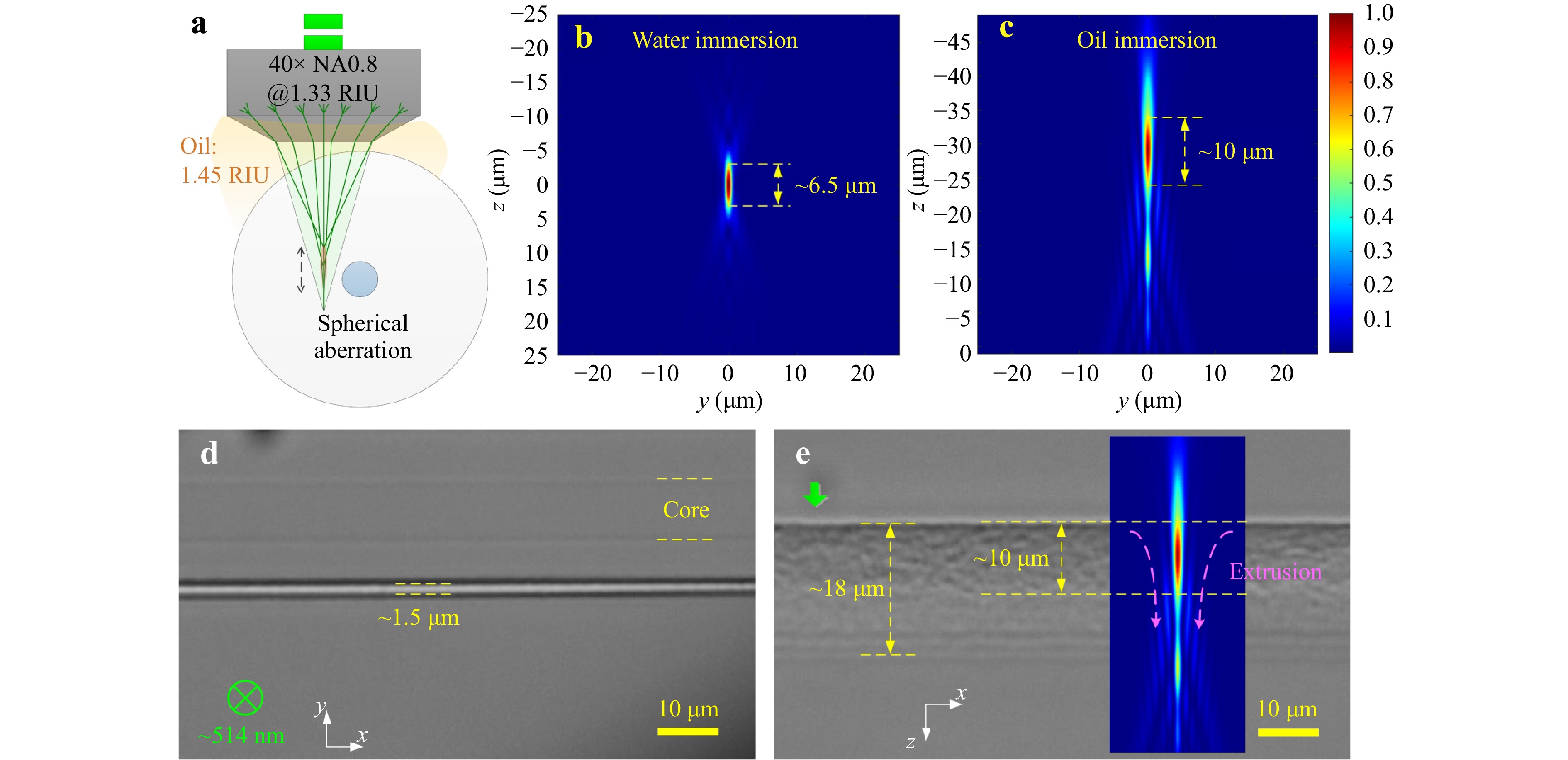

The identical responses of fiber Bragg grating (FBG) sensors to temperature and strain limit their practical applications. To address this challenge, we propose and demonstrate a monofiber sensor capable of discriminating between temperature and strain by leveraging the distinct thermo-optic properties of two heterogeneous waveguides. Specifically, a pair of waveguide Bragg gratings was inscribed in different sections of a panda polarisation-maintaining fiber (PMF) using spherical-aberration-assisted femtosecond (fs) laser fabrication. When subjected to temperature changes, the two Bragg resonance peaks exhibited distinct responses, whereas their strain responses remained consistent. Consequently, the monofiber sensor achieves discrimination without requiring additional isolated compensation. The proposed sensor demonstrates an order-of-magnitude improvement in strain measurement accuracy compared to conventional isolated temperature-compensation methods under dynamic temperature changes.

Published

, Published online: 25 November 2025

, doi: 10.37188/lam.2025.080

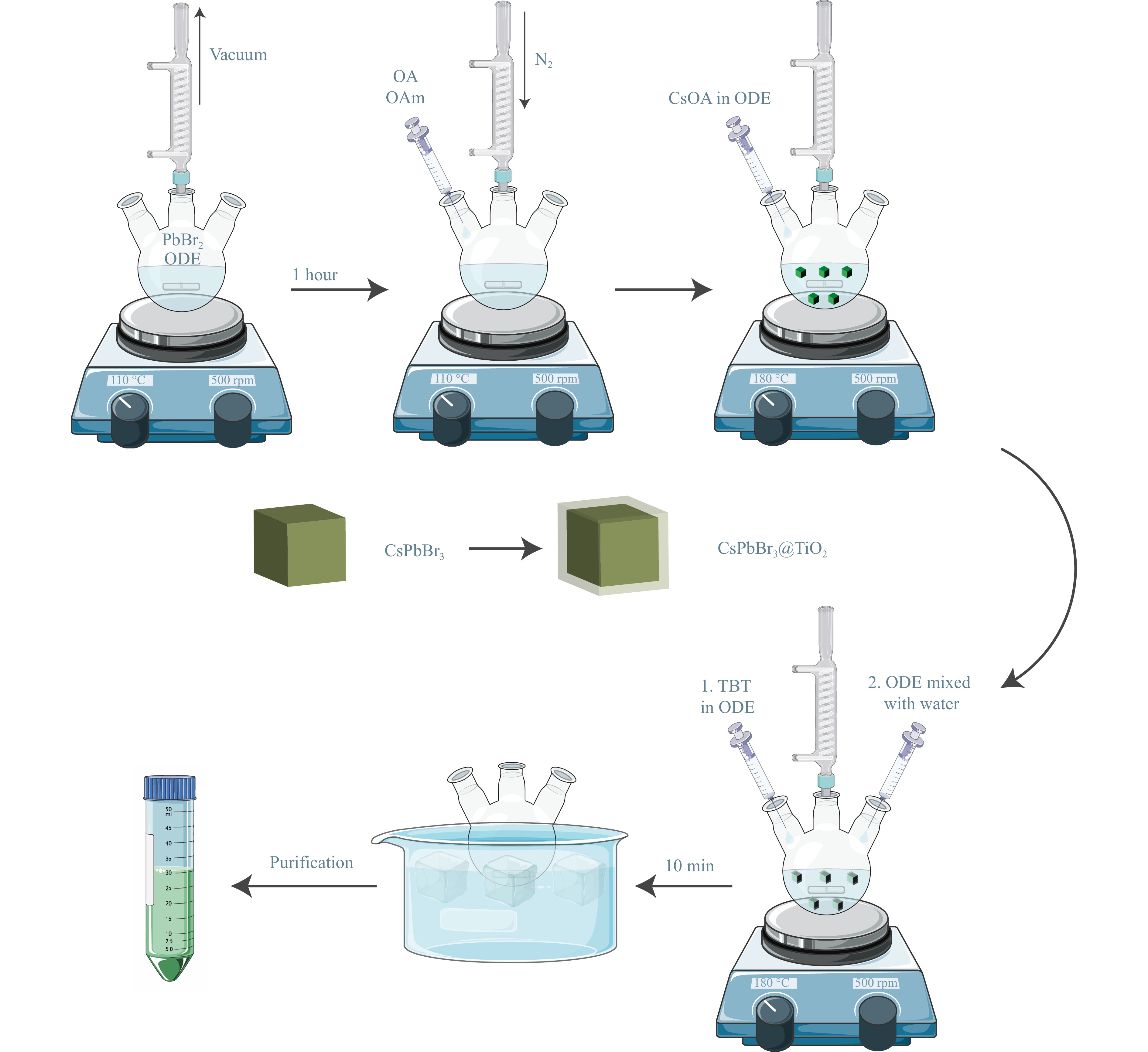

Perovskite photoelectrocatalysis enables solar-driven conversion of CO2 to value-added chemicals, but instability in water and insufficient C–C coupling still constrain performance. Herein, we present a synergistic approach for aqueous-phase CO2 conversion that combines perovskite-based photoelectrocatalysis with localized surface plasmon resonance (LSPR) enhancement. To address the inherent instability of lead-halide perovskites, we developed a modified hot-injection route that enables the in situ formation of water-stable CsPbBr3@TiO2 core–shell nanoparticles. Titanium butoxide and water were introduced after Cs-oleate injection, enabling controlled TiO2 shell growth without post-treatment. Electron microscopy, XRD, and XPS confirm the core–shell architecture, while optical/electrical probes indicate efficient charge separation across the CsPbBr3/TiO2 junction. Subsequently, we investigated electrocatalytic, photocatalytic, and photoelectrochemical carbon dioxide reduction (CO2RR) on CsPbBr3@TiO2/Au and CsPbBr3@TiO2. Gas chromatography revealed tunable product selectivity, yielding H2, CO, CH4, and multicarbon (C2, C3) products including C2H4 (ethylene) and C3H6 (propene). Our main findings indicate that the CsPbBr3@TiO2/Au exhibits high selectivity toward C3 (propene) in photocatalysis and C2 (ethylene) in photoelectrochemistry, reaching up to 70% and 58%, respectively. These results highlight perovskite heterostructures as a viable platform for efficient CO2 utilization and the sustainable production of value-added C2/C3 chemicals.

Published

, Published online: 25 November 2025

, doi: 10.37188/lam.2025.079

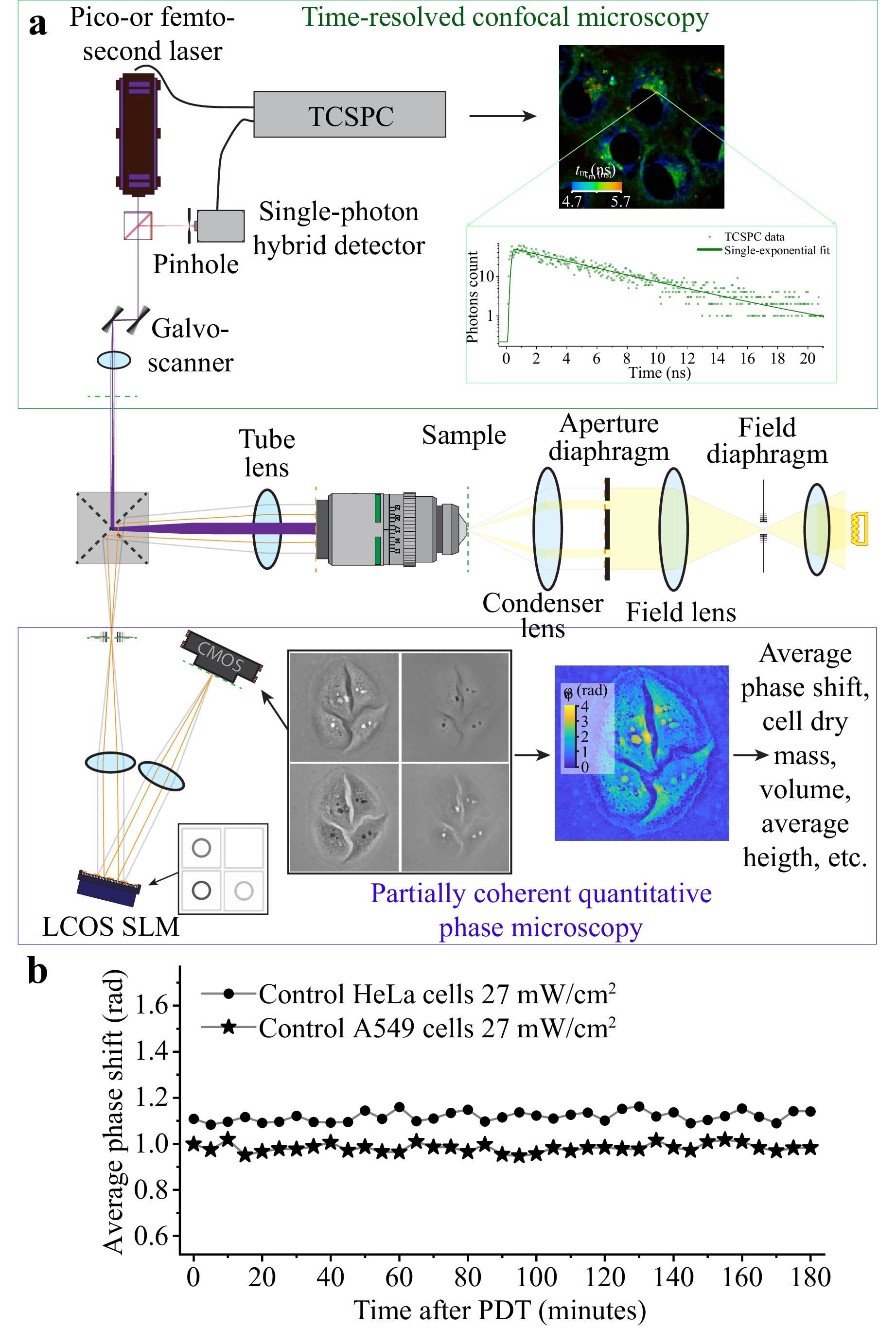

This paper presents a multimodal approach that combines time-resolved fluorescence microscopy and spatial light interference microscopy into a single complex allowing for a concurrent comprehensive analysis of cell samples in vitro. The combined application of quantitative phase imaging using partially coherent radiation with time-resolved fluorescence imaging of endogenic coenzymes NADH and FAD, as well as Radachlorin photosensitizer, allowed for evaluation of a set of morphological and physiological parameters of cells of the two lines, HeLa and A549, in the course of photodynamic treatment. Besides comparison of cells of the two lines in terms of volume, height, dry mass, projected area, and redox ratio, we analysed the mechanisms and rate of Radachlorin accumulation. Using the developed multimodal approach, we demonstrated that in both the cell lines, Radachlorin was taken up in complexes with serum albumin, transported by endocytosis, and accumulated primarily in lysosomes. The Radachlorin transportation through the cellular membrane to lysosomes was accompanied by a decrease in its fluorescence lifetime, which was apparently owing to a gradual increase in endosome acidity. The different contributions of the fast and slow components of time-resolved fluorescence signals of nicotinamide adenine dinucleotide (NADH) and flavin adenine dinucleotide (FAD) enabled us to demonstrate the difference in the redox ratios of cells of the two lines. The average concentration of the accumulated Radachlorin photosensitizer in cells of the two lines and their resistivity to photodynamic treatment also differed: HeLa cells tended to accumulate more Radachlorin and demonstrated lower resistivity to photodynamic treatment.

Published

, Published online: 11 November 2025

, doi: 10.37188/lam.2025.078

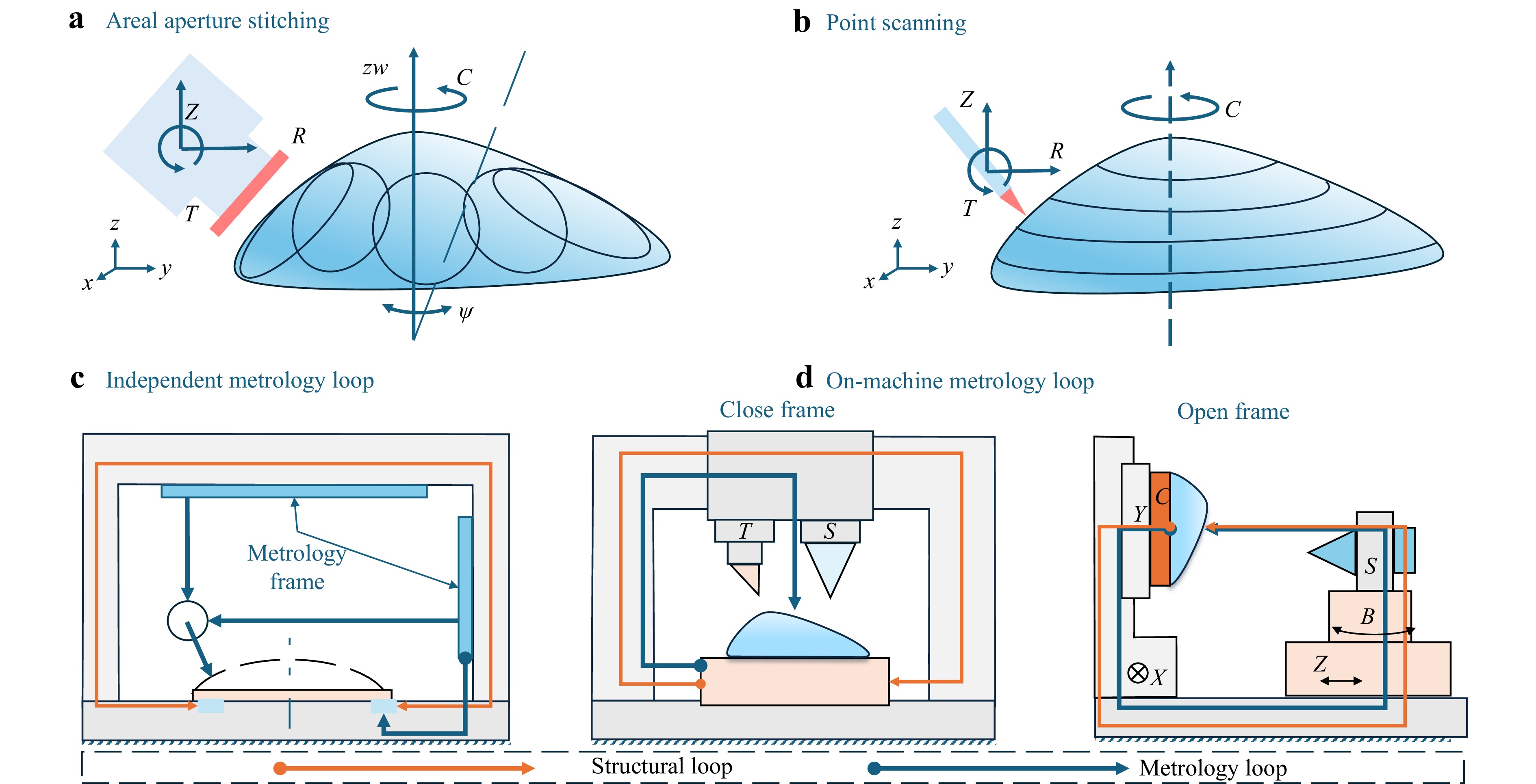

Metrology challenges have increasingly been the bottleneck in the manufacturing of freeform optics. On-machine metrology has emerged as a potential solution to bridge the gap between measurement and machining processes. It is widely recognised that metrology systems integrated with manufacturing platforms are affected by the dynamic characteristics of the host platform. However, there is a limited understanding of how these dynamic disturbances contribute to measurement error, primarily due to a lack of comprehensive system-level analysis. This paper aims to depict the relationship between mechanical vibration and measurement error in an on-machine surface measurement (OMSM) system and proposes a method to mitigate this error through system calibration. A dynamic error model of the OMSM system is developed, incorporating feed disturbances, machine dynamics, and the compliance of the measurement units. Our analysis identifies phase lag in the measurement unit as a primary contributor to the distortion of the measured surface figure. To address this issue, a calibration procedure is performed based on system transfer function identification. The proposed calibration method effectively reduces the residual error in high-speed measurements. Experimental results demonstrate a reduction of the peak-to-valley (PV) error from 6 µm to 0.5 µm, and a decrease in the root mean square (RMS) error from 2.3 µm to 20 nm. Using this system, a high-density point cloud of 290,000 points was measured in 6 minutes, successfully meeting the challenges of measuring freeform surfaces on the manufacturing platform with both high accuracy and high efficiency. The proposed calibration method, which compensates for the absence of an independent metrology frame, can be adapted for other similar on-machine systems. This approach offers a cost-effective and time-efficient solution for the rapid prototyping of freeform optical components using integrated surface metrology.

Published

, Published online: 06 November 2025

, doi: 10.37188/lam.2025.073

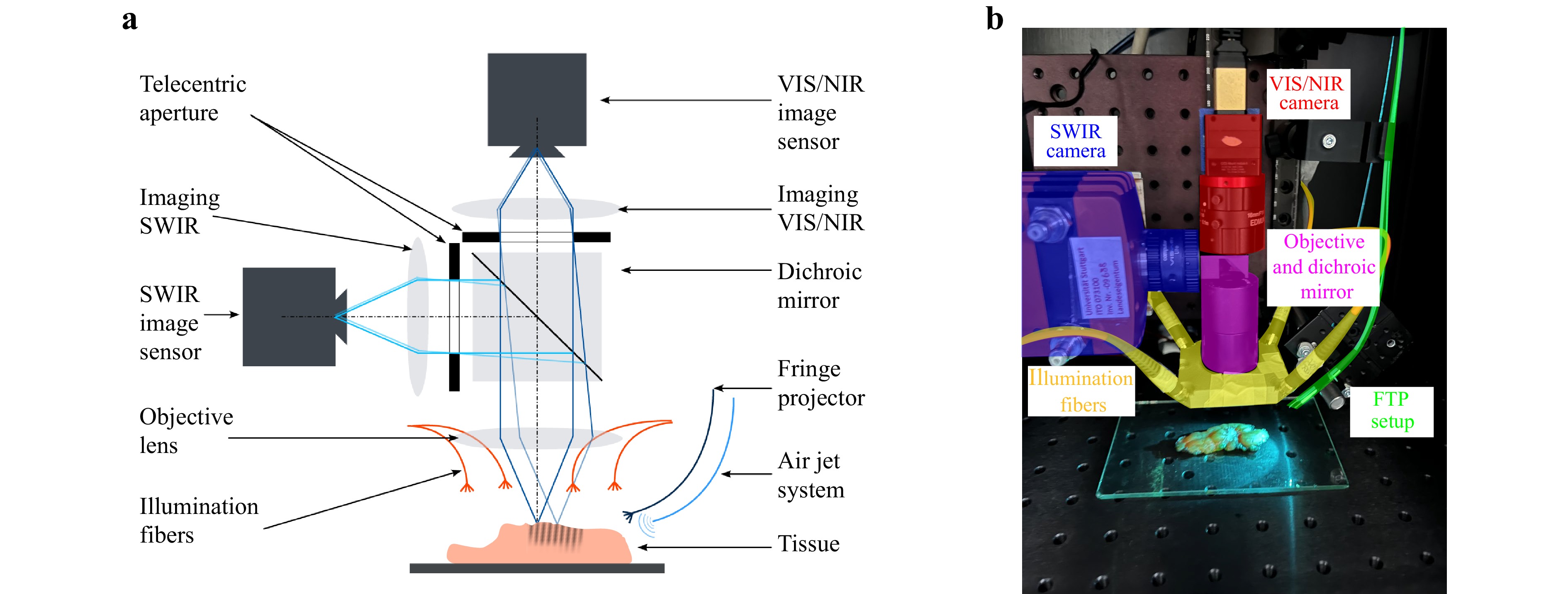

Multispectral imaging is a common method to enhance tissue differentiation based on different cell or tissue structures. These differences arise from the unique structural properties of each tissue type, which result in characteristic differences in spectral absorption. In the context of distinguishing between healthy and malignant tissues, differences are observed not only in spectral absorption but also in their elastic properties. To improve the reliability of measurement devices, we present a novel bimodal measurement system that includes a hyperspectral and an elastographic Fourier transform profilometry system to combine the individual results and to improve the overall task of tissue differentiation. The results of both subsystems show good ability to differentiate between healthy and malignant tissue. However, some limitations were identified for each individual sensor concept, such as contamination with pathological dye in hyperspectral imaging and insufficient sample thickness in elastographic measurements. Nevertheless, the multimodal combination of the individual sensor systems ensures good tissue differentiation. While the elastographic sensor can differentiate tissue even when contaminated with pathological staining agents, hyperspectral imaging can be used on very thin tissue samples and also enables the detection of tumor boundaries.

Published

, Published online: 05 November 2025

, doi: 10.37188/lam.2025.046

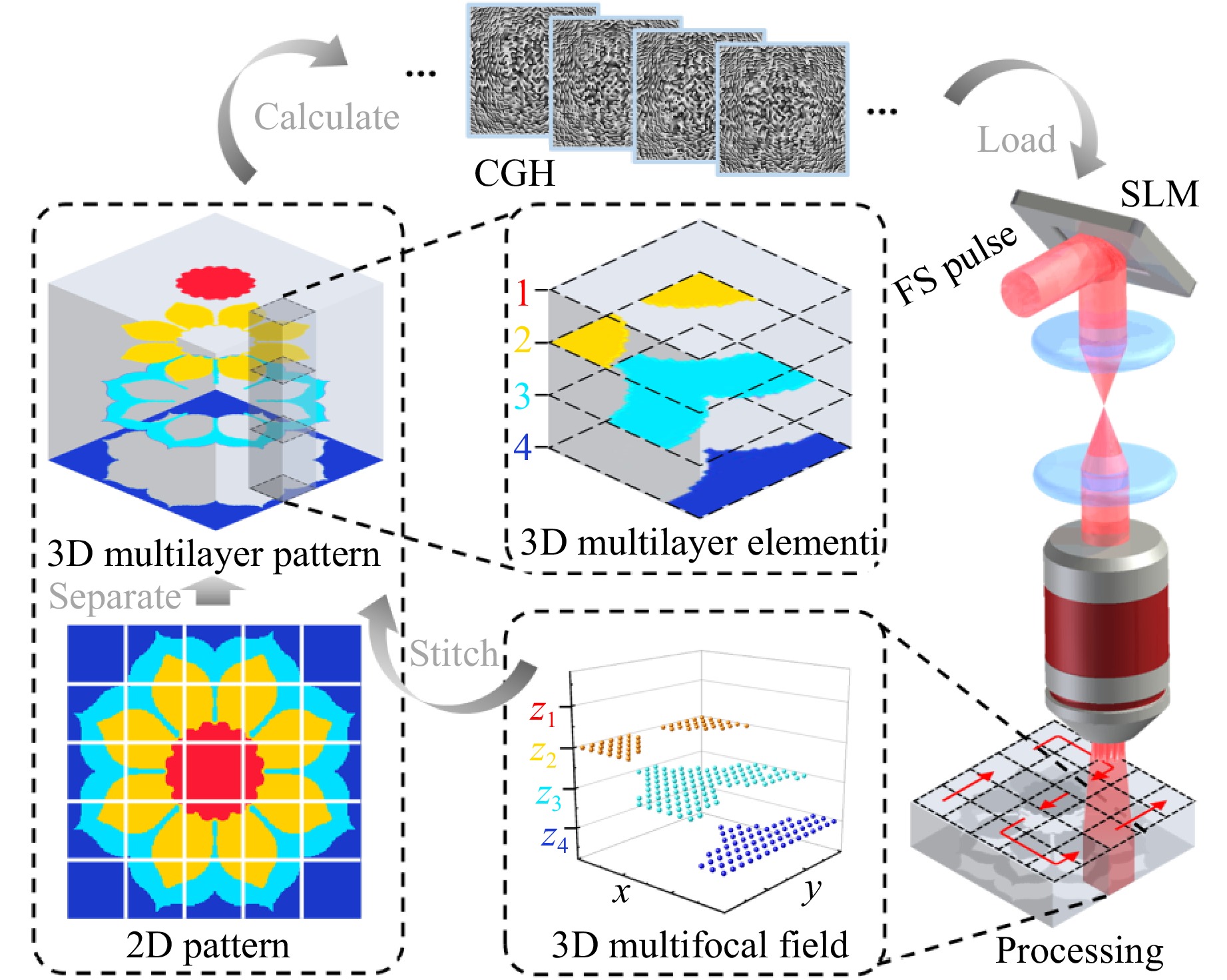

Holographic patterns that integrate printings and holograms into a single device have received extensive attention in optical security owing to their attractive aesthetics and concealment. However, the sophisticated structures of metasurface-based optical devices require a time-consuming fabrication process, hindering the practical application of holographic patterns in optical security. In this study, a novel double-layer holographic pattern that employs simple microholes and microvoids as optical modulation units is designed and experimentally demonstrated. The two layers of the structure arrays are synchronously processed in a transparent material through a single serial-stitching of dynamic 3D spatially modulated femtosecond pulses that are proposed for the rapid fabrication of large-area multi-layered patterns. The fabricated holographic pattern appears as a dynamic grayscale image under white light incident at different angles and projects encoded holographic images under laser illumination. By transforming microholes into microcraters by ultrasonic treatment, the reconfiguration of the holographic pattern can be realized based on refractive index modulation using liquid immersion. The proposed reconfigurable holographic patterns with simple structures and visible sizes enable the recoding of multiple pieces of information, making them practical optical security elements with a wide range of applications in anti-counterfeiting and information encryption.

- First

- Prev

- 1

- 2

- 3

- 4

- 5

- 6

- 7

- 8

- 9

- 10

- Next

- Last

- Total:18

- To

- Go

Email

Email RSS

RSS